How Skid-Mounted Systems Redefine Safety and Efficiency

Revolutionizing LNG Shipping: How Skid-Mounted Systems Redefine Safety and Efficiency

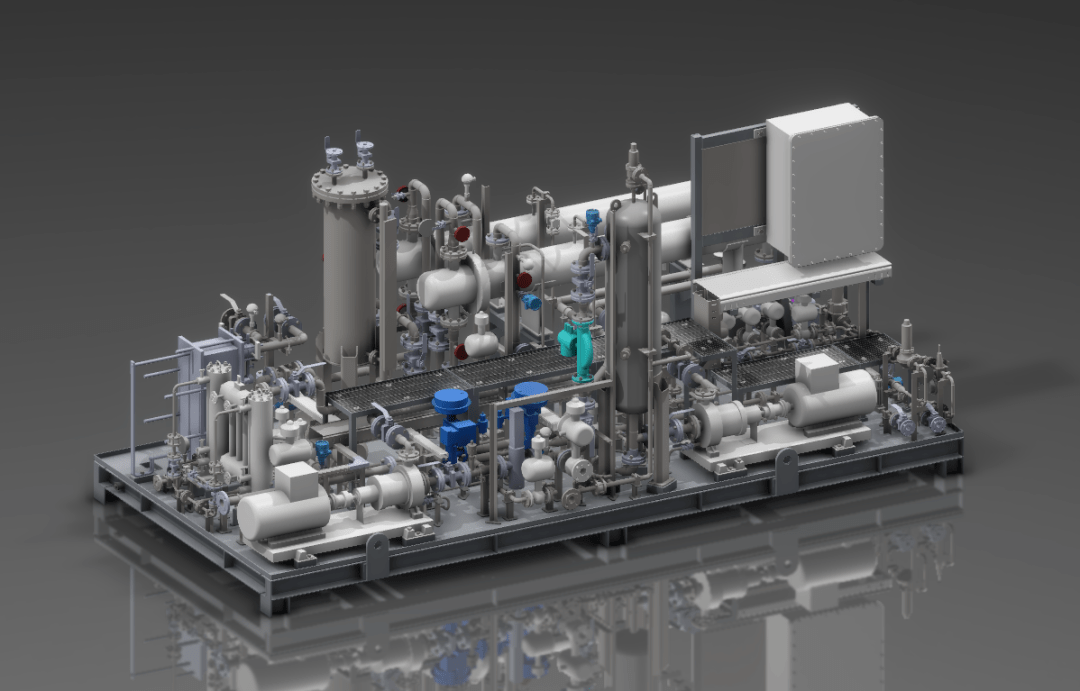

In the high-stakes world of liquefied natural gas (LNG) transportation, where cargo temperatures plunge to -162°C and flammable vapors demand zero-tolerance safety, skid-mounted systems emerge as the unsung engineering heroes. These pre-engineered modules – integrating processing, safety, and control functions onto compact steel frames – are transforming vessel design, construction, and operation. Here’s how their cutting-edge features position them at the core of next-generation LNG shipping.

Ⅰ. Core Design Philosophy: Modularity Meets Mission-Critical Reliability

Skid systems replace traditional scattered piping networks with integrated plug-and-play units, achieving:

50% faster installation vs. stick-built alternatives by enabling parallel construction workflows

30% weight reduction through topology-optimized frame designs validated by finite element analysis (FEA)

Triple-layered redundancy in safety systems to meet IGC Code’s "no single point of failure" mandate

Example: BOG (Boil-Off Gas) handling skids consolidate compressors, cryogenic valves, and control logic into a single 8m x 4m footprint – slashing engine room space requirements by 40%.

Ⅱ. Safety by Design: Engineering Against Catastrophe

1. Cryogenic Containment Innovations

Thermal Shock-Resistant Materials: Invar® alloy (Fe-Ni-Cr) joints absorb -196°C to 50°C thermal cycles without cracking, preventing brittle fracture

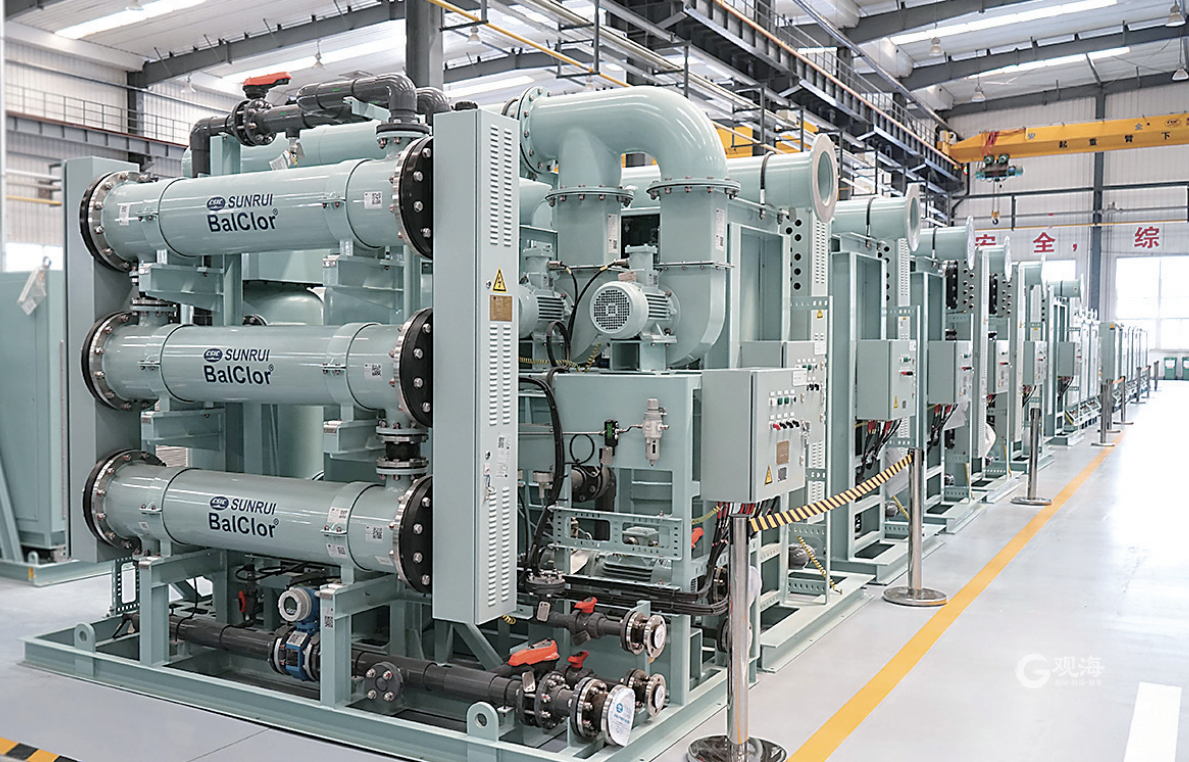

Bursting Disc Safeguards: Bi-metal rupture discs (shown in Figure 2) automatically open at preset pressures/temperatures, diverting LNG leaks to drip pans within 500ms

Hermetic Sealing: Laser-welded stainless steel bellows eliminate flange gaskets – the #1 source of fugitive emissions

2. Explosion Prevention Systems

| Component | Function | Innovation |

|---|---|---|

| Oxygen Analyzers | Continuous inert gas monitoring | Zirconia ceramic sensors with ±0.1% accuracy |

| Emergency Shutdown (ESD) | Isolates leaks in < 2 seconds | SIL-3 certified hydraulic actuators |

| Vapor Detection | Identifies 1 ppm hydrocarbon traces | Quantum cascade laser (QCL) spectroscopy |

Ⅲ. Smart Integration: The Digital Nerve System

Modern skids embed Industry 4.0 technologies that transform passive hardware into responsive assets:

Digital Twin Synchronization: Live sensor data (pressure/temp/flow) mirrors physical skids in virtual models, enabling predictive maintenance

Edge AI Processors: On-skid NVIDIA Jetson modules run anomaly detection algorithms, cutting false alarms by 65%

WirelessHART Mesh Networks: Eliminate 85% of cabling while providing < 10ms control loop response

Case Study: A Moss-type LNG carrier reduced unplanned downtime by 78% after retrofitting smart BOG skids with vibration analytics.

Ⅳ. Material Science Breakthroughs

1. Advanced Metallurgy

9% Nickel Steel: Withstands -196°C cryogenic stress at 50% lower weight than stainless steel

Glass-Foam Composites: Multi-layer insulation (MLI) panels achieve 0.15 W/m·K thermal conductivity – halving BOR (Boil-Off Rate)

2. Anti-Corrosion Defense

Cold Spray Aluminum Coating: Zinc-aluminum matrix protects carbon steel frames from saline corrosion, extending service life to 30+ years

Cathodic Protection Skids: Impressed current systems monitor hull potential, adjusting voltage to prevent electrolytic decay

Ⅴ. Sustainability Drivers: Emissions & Efficiency

Waste Heat Recovery: Thermoelectric generators (TEGs) convert exhaust heat into 50 kW/skid auxiliary power

Zero-VOC Seal Technology: Perfluoroelastomer (FFKM) gaskets eliminate methane slip during valve cycling

Hydrogen-Ready Design: Dual-fuel skid manifolds accept 40% H₂-NG blends for future fuel transitions

Data Point: Wärtsilä’s LNG cargo skids reduced CO₂-equivalent emissions by 11,000 tons/vessel/year via optimized BOG management

.

Ⅵ. Industry-Specific Applications

| Skid Type | Function | Key Innovation |

|---|---|---|

| BOG Re-liquefaction | Compresses & chills vapor to -163°C | Oil-free turbo-Brayton cycle compressors |

| Cargo Conditioning | Maintains tank pressure at 110 kPa ±5% | Proportional-integral-derivative (PID) cryovalves |

| Nitrogen Generation | Produces 99.9995% pure N₂ for inerting | Hollow-fiber membrane separation skids |

| Cold Energy Harvest | Converts LNG cold to electricity | Rankine cycle turbines with R718 refrigerant |

The Future: Self-Optimizing Skids

Emerging technologies set to redefine LNG skids by 2030:

Autonomous Leak Repair: Micro-encapsulated healing agents released by pH-sensitive polymers seal cracks in situ

Quantum Sensing Arrays: SQUID (Superconducting Quantum Interference Device) magnetometers detect pipe corrosion at 5mm depth

Additive Manufacturing: On-vessel 3D printing of replacement parts using wire-arc deposition (WAD)

Why Skid Systems Matter Now

For LNG operators navigating decarbonization mandates and volatile gas markets, skid-mounted systems deliver unprecedented safety density, operational agility, and lifecycle economy. As demonstrated by GTT’s NO96-L03+ membrane containment and Moss-type spherical tanks

, modular engineering isn’t just an upgrade—it’s the cornerstone of next-generation LNG shipping.