Reducing Carbon Footprint with Efficient Skid Systems

2026-02-06 21:48Reducing Carbon Footprint with Efficient Skid Systems

Optimized Process Efficiency and Energy Integration

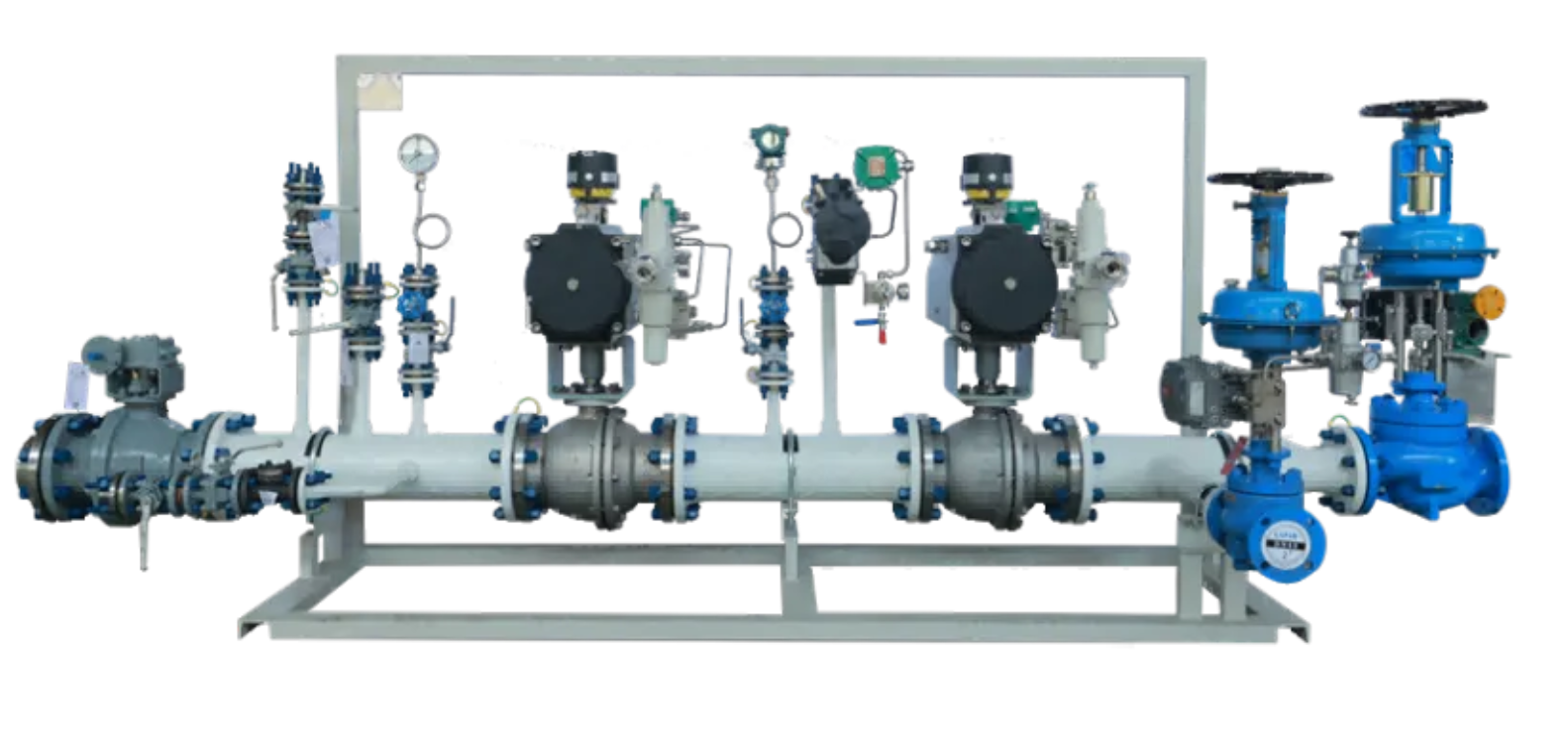

The most significant contribution of efficient skid systems to carbon footprint reduction lies in their core design principle: process optimization. Unlike traditional field-erected systems, which often involve compromises due to on-site constraints, skid modules are engineered in a controlled factory environment with a singular focus on maximizing energy efficiency. This allows for the precise integration of heat recovery systems, where waste heat from one process stream is captured and reused to pre-heat another, dramatically reducing the primary energy demand from fossil fuels. Furthermore, advanced process simulation and computational fluid dynamics (CFD) modeling during the design phase enable engineers to minimize pressure drops, optimize pump and compressor sizing, and select highly efficient components. For instance, a well-designed pumping skid from Shanghai Shenqi Machinery can achieve the same throughput with a smaller, variable-speed drive motor, leading to substantial electricity savings over its operational lifetime. This inherent focus on optimal performance directly translates to lower fuel and power consumption, resulting in a significant reduction in greenhouse gas emissions from day-to-day operations.

Minimized Material Waste and Sustainable Construction Practices

The prefabricated nature of skid systems champions sustainability from the very beginning of the manufacturing lifecycle. Factory-controlled fabrication, as practiced by Shanghai Shenqi Machinery, leads to a drastic reduction in material waste compared to traditional construction. Precision cutting of pipes and plates, guided by digital models, maximizes material utilization. Leftover materials can be systematically managed and recycled within the factory setting, a stark contrast to the dispersed and often non-recyclable waste generated at construction sites. Moreover, the modular design allows for the use of optimized, lighter-weight structures without compromising integrity, reducing the overall steel footprint. This approach not only conserves raw materials but also lowers the embodied carbon associated with material production and transportation. By delivering a pre-assembled unit, the skid approach also eliminates the need for excessive on-site construction materials and their associated packaging, further minimizing the environmental impact of the project's installation phase.

Enhanced System Longevity, Maintenance, and Circular Economy

Efficient skid systems are built to last, which is a fundamental aspect of sustainability. The high-quality, controlled fabrication process results in superior equipment longevity and reliability. A longer operational lifespan means fewer resources are consumed over time for manufacturing replacement units, thereby reducing the lifecycle carbon footprint. Furthermore, the centralized and accessible design of skids simplifies preventive maintenance, allowing for quicker inspections and repairs. This not only ensures the system continues to operate at peak efficiency but also prevents minor issues from escalating into major failures that would require energy-intensive fixes or complete replacement. The skid's modularity also supports the principles of the circular economy. At the end of its life on one site, or if process needs change, the entire skid or its major components can be decommissioned, refurbished, and redeployed elsewhere. This "reuse" model, facilitated by companies like Shanghai Shenqi, stands in direct opposition to a disposable mindset, conserving the significant energy and resources initially invested in the system's creation.

In summary, efficient skid systems are a powerful tool for industrial decarbonization. They achieve this not through a single feature, but through a holistic approach that combines superior process efficiency, waste-minimized manufacturing, and extended asset lifecycle. By investing in high-quality, optimized skid modules from experienced providers like Shanghai Shenqi Machinery, industries can significantly reduce their energy consumption, material waste, and overall carbon emissions, aligning operational excellence with environmental responsibility for a more sustainable future.