Speeding Up Project Timelines with Prefabricated Pipelines

2025-12-31 13:56Speeding Up Project Timelines with Prefabricated Pipelines

In today's fast-paced industrial landscape, project delays are costly. Prefabricated pipelines are revolutionizing construction, offering a smarter, faster, and more reliable alternative to traditional field welding. Discover how this "modular magic" is setting new standards for efficiency and quality.

How Off-Site Fabrication Beats Weather and Delays

Traditional pipeline installation is at the mercy of the elements. Rain, wind, and extreme temperatures can halt progress for days or even weeks, causing costly overruns. Prefabricated pipelines, expertly crafted by suppliers like Shanghai Shenqi, turn this model on its head. By shifting the critical welding, fitting, and assembly work to a controlled factory environment, project timelines become predictable and resilient. While site preparation and foundation work proceed outdoors, the pipeline spools are manufactured simultaneously indoors. This parallel approach eliminates the sequential bottlenecks of traditional methods, slashing overall project duration by up to 50% or more. The result is a dramatic reduction in weather-related risks and a guaranteed acceleration of your project's critical path, ensuring you meet tight deadlines with confidence.

Precision Engineering in a Controlled Environment

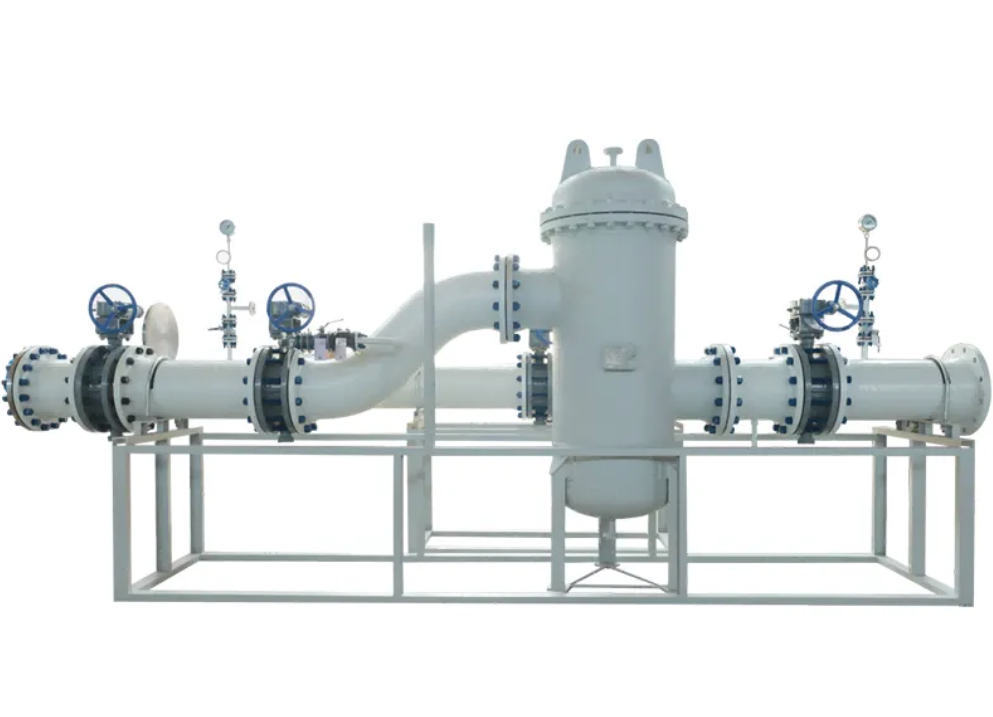

Speed is meaningless without quality. Field welding, often performed in challenging conditions, can lead to inconsistencies, defects, and potential safety hazards. Prefabrication ensures a level of quality that is nearly impossible to achieve on-site. In Shanghai Shenqi's workshop, pipelines are assembled using advanced jigs and fixtures, guaranteeing perfect alignment. Highly skilled welders perform their craft under optimal conditions, resulting in stronger, more consistent welds that are meticulously inspected using non-destructive testing (NDT) methods. Every component, from elbows to valves, is precisely fitted according to digital isometric drawings, minimizing the risk of error. This controlled process delivers a product that meets the highest international standards, reducing the need for rework and ensuring long-term system integrity and safety from the very start.

Simplifying Installation and Reducing Labor Risks

The final triumph of prefabricated pipelines is realized the moment they arrive on-site. Instead of a chaotic scene of cutting, fitting, and welding, the installation process becomes a streamlined assembly operation. Each clearly marked spool is simply lifted into place and connected, like building blocks. This "plug-and-play" approach significantly reduces the required skilled labor and the associated costs and safety risks of prolonged hot work on site. It also minimizes disruption to ongoing operations, a critical advantage for plant turnarounds or expansions. The speed and simplicity of installation mean that your system can be operational in a fraction of the time, allowing you to start generating revenue or achieving operational efficiencies much sooner than with traditional methods.

Prefabricated pipelines are more than just a time-saving technique; they represent a fundamental shift towards smarter, more reliable industrial construction. By leveraging the modular magic of off-site fabrication, companies can de-risk projects, guarantee quality, and achieve unparalleled speed to market, turning time from a constraint into a competitive advantage.