- Home

- >

- Products

- >

- Ball valve

- >

Ball valve

High performance flexible floating seat

Design principle: lip shape seal technology

Size scope:1-4inch

Applicable temperature: -46℃~250℃

Applicable pressure:RPTFE:150Lb-600Lb ,PTFE:150LbDEVLON:150Lb-2500Lb NYLON:150Lb-2500LbPEEK:150Lb-2500Lb

- Information

l Application

Floating ball valves are small in size, light weight, simple structure, good sealing, but ball work under medium load to export all seals and therefore to consider sealing material can with stand sphere medium work loads.

l Main Specs

High performance flexible floating seat

Design principle: lip shape seal technology

Size scope:1-4inch

Applicable temperature: -46℃~250℃

Applicable pressure:RPTFE:150Lb-600Lb ,PTFE:150LbDEVLON:150Lb-2500Lb NYLON:150Lb-2500LbPEEK:150Lb-2500Lb

l Technology features

1. Lip shape seal design.The rubber will occur large deformation under pressure to offset the roughness of metal surface, and can recover its original shape when stress relief. This material is called as “ Memory Property". We plan to create a new seat material that can overcome the defects of PTFE cold flow and thermal expansion and improve the memory property.This sealing structure is called as Lucky Lip Seal Technology.

2. Double layers sealing structure the lip shape seal seat has the advantages that its position will be changed due to high temperature, which will form double points sealing, sealing performance is more reliable.

3.Back pressure deformation structure There is a certain radian on the back side of the seat to prevent the right angle from being deformed, and it also can improve the lip shape seal seat elasticity.

4.Shape deformation structure The radian angle on the seat mainly avoid the higher extrusion stress occurred because of the deformation of the lip shape seal seat.

No. | Components | Carbon steel | stainless steel | Acid condition | Cryogenic condition |

1 | Handle | WCB | WCB | WCB | WCB |

2 | Screws | ASTM A193-B7 | ASTM A193-B8 | ASTM A193-B7M | ASTM A193-L7 |

3 | Packing gland | Carbon steel | ASTM A315-CF8M | Carbon steel | ASTM A352-LCB |

4 | Gaskets | 316SS+graphite | 316SS+graphite | 316SS+graphite | 316SS+graphite |

5 | Packing | Graphite | Graphite | Graphite | Graphite |

6 | Stem | ASTM A182-F6a | ASTM A182-F316 | ASTM A182-F6a | ASTM A182-F316 |

7 | Spring | Stainless steel | Stainless steel | Stainless steel | Stainless steel |

8 | Steel balls | Stainless steel | Stainless steel | Stainless steel | Stainless steel |

9 | Bolt | ASTM A193-B7 | ASTM A193-B8 | ASTM A193-B7M | ASTM A193-L7 |

10 | Nuts | ASTM A194-2H | ASTM A194-8 | ASTM A194-2HM | ASTM A194-7 |

11 | Body | ASTM A216-WCB | ASTM A315-CF8M | ASTM A216-WCB | ASTM A352-LCB |

12 | Bonnet | ASTM A216-WCB | ASTM A315-CF8M | ASTM A216-WCB | ASTM A352-LCB |

13 | Seat | PTFE | PTFE | PTFE | PTFE |

14 | Ball | ASTM A105 ENP | ASTM A182-F316 | ASTM A105 ENP | ASTM A350 LF2 ENP |

Advantages

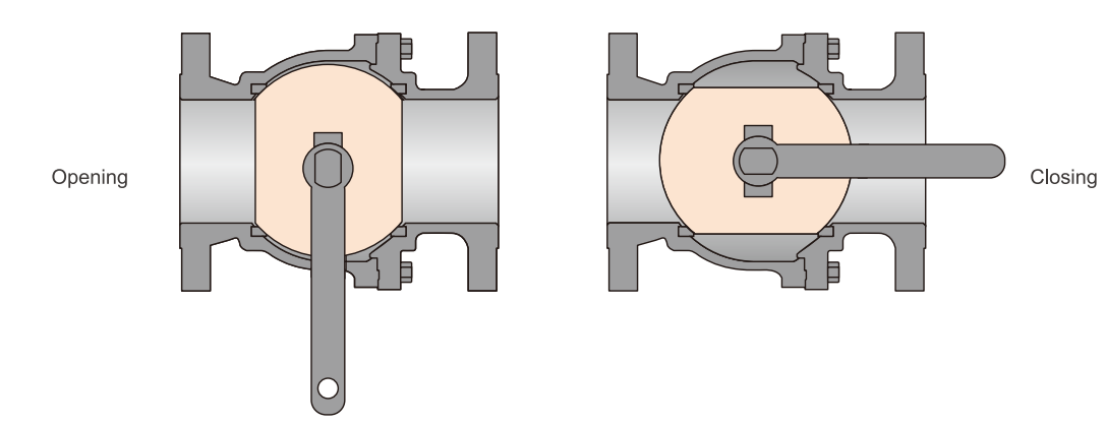

Avoid Wrongly Operate Lever

The opening and closing of valves are often confirmed by the position of the handle, which is perpendicular to the pipeline when the handle is parallel to it. However, the connection between the handle and valve stem of a regular ball valve is flat and square, which can easily cause valve misoperation due to incorrect connection between the handle and valve stem. The connection between the handle and stem of our floating ball valve is flat square, which cannot cause the handle to be connected incorrectly, let alone misoperation.

-Ball Valve with Locking Device

The manual ball valve can be locked with a lock in the fully open and fully closed positions to prevent accidental operation of the valve caused by non staff personnel pulling the handle. It can also prevent accidents caused by pipeline vibration or unpredictable factors leading to valve opening or closing. Especially for work pipelines such as explosive oil and chemical drugs, or outdoor piping situations, it has a more effective effect.

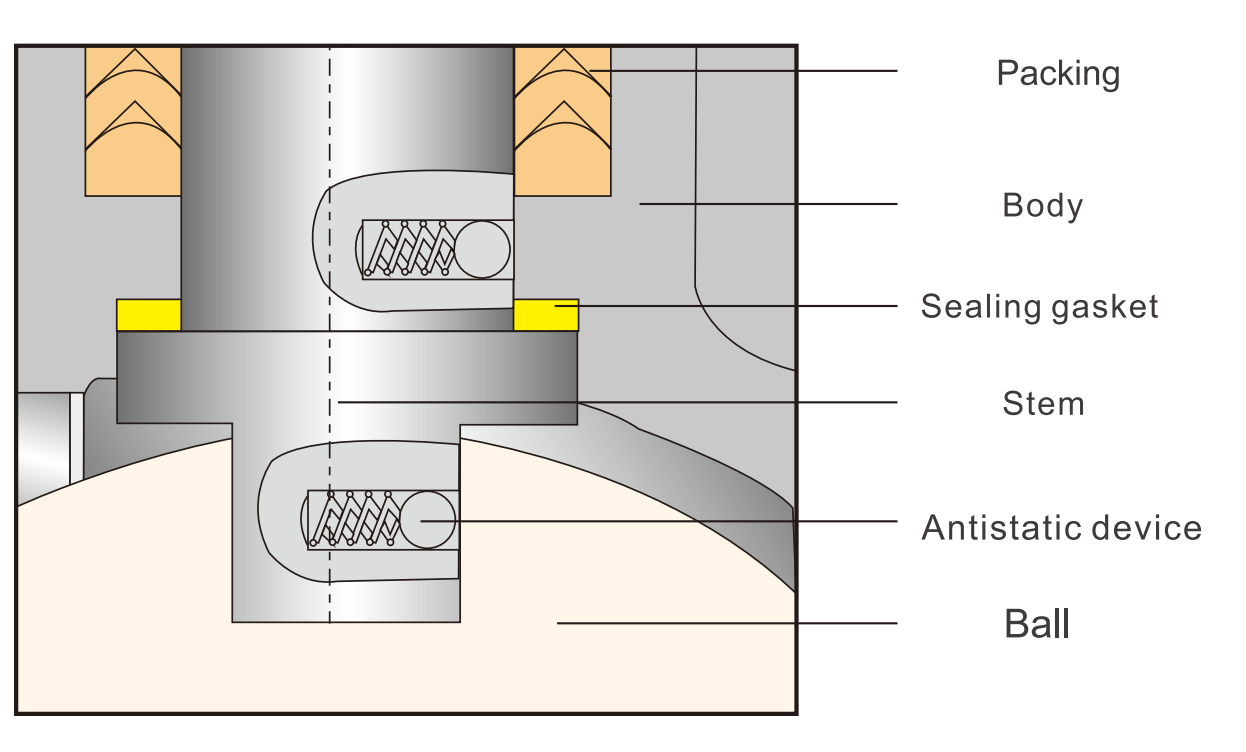

Jet Proof Stem Shoulder

Floating ball valve is equipped with a shoulder at the lower part of the valve stem to prevent the risk of the valve stem flying out due to abnormal pressure rise inside the valve. In addition, to prevent leakage caused by burning of the valve stem sealing gasket in case of fire, a thrust bearing is installed at the lower shoulder of the valve stem in contact with the valve body to form a reverse sealing seat, preventing leakage and avoiding the expansion of accidents. For ordinary ball valves, if the valve stem and packing are burned, or if the packing cover and bolts are damaged, the valve stem is prone to fly out under internal pressure, causing fluid overflow and accidents. The increase in value increases the severity of the accident, which is not allowed by safety requirements.

Anti-static Performance

Our floating ball valve is designed to prevent static electricity from being generated due to friction between the ball and valve stem with TFE (or RPPI), which can easily ignite flammable and explosive media and cause working accidents. Static conductive springs are installed between the valve stem and ball, as well as between the valve stem and valve body, to allow static electricity to be introduced into the ground through pipelines, ensuring system safety.

Fire Proof Protective Structure

In order to prevent the occurrence of a fire and prevent significant leakage when the valve seat is burned, which could fuel the fire, Chenggong ball valve is equipped with a fireproof sealing ring between the ball and the valve seat. When the valve seat is burned, the medium quickly pushes the ball towards the metal sealing ring at the downstream end, forming a metal to metal contact and providing a certain degree of sealing. Thus ensuring the security of the system. In addition, there are corresponding fireproof structures at the connection between the valve body and the auxiliary valve body, as well as at the sealing of the valve stem.

-Special Seat Structure

With years of manufacturing experience, we have designed a double sealed valve seat structure with elastic force, which has excellent sealing effects for high pressure, low pressure, and vacuum states,