Industrial Primary Gas Regulator 1.72MPa | DN50 NPT Ports | SG15 Safety Rated

HEAVY-DUTY 1.72MPa INPUT - Industrial-grade resilience for pipeline pressures up to 250 PSI

DIRECT-ACTING PRECISION - AC10-certified ±1.5% pressure stability across 0.03-0.56MPa outputs

DN25/DN50 NPT PORTS - Dual-sized female threads enable flexible piping configurations

500 Nm³/h HIGH FLOW - Sustains demand for commercial boilers & manufacturing plants

ARCTIC TO DESERT RELIABILITY (-20°C~60°C) with nickel-plated internals preventing corrosion

- SQ

- Shanghai

- 7-15days

- 20000 sets

- Information

Industrial Primary Gas Pressure Regulator - RTZ Series

Precision Pressure Control for Critical Gas Infrastructure

I. Engineering Excellence & Technical Specifications

1.1 Robust Pressure Management Capabilities

This industrial-grade primary regulator delivers uncompromising performance in demanding environments. Engineered with direct-acting spring-load technology, it achieves AC10 precision classification (ISO 10533 standard) - maintaining outlet pressure within ±2.5% deviation across extreme flow fluctuations. The system handles:

Maximum Inlet Pressure (P1): 1.72MPa (250 PSI)

Configurable Outlet Ranges (P2):

Tier 1: 0.03~0.14MPa (4.3~20.3 PSI)

Tier 2: 0.1~0.28MPa (14.5~40.6 PSI)

Tier 3: 0.28~0.56MPa (40.6~81.2 PSI)

Peak Flow Capacity: 500 Nm³/h (17,657 SCFH)

1.2 Certified Safety Architecture

Featuring SG15-rated shutoff mechanism (EN 88-1 certified), the regulator:

Activates emergency closure within 0.8 seconds during 150% overpressure events

Maintains seal integrity at 60°C ambient temperatures

Withstands 100,000+ pressure cycles without seal degradation

1.3 Extreme Environment Resilience

Operational parameters exceed industry standards:

Temperature Range: -20°C to +60°C

Materials Engineering:

Body: ASTM A536 Ductile Iron (Grade 65-45-12)

Diaphragm: Nitrile-Butadiene Matrix (3mm reinforced)

Springs: EN 10270-1 Cold Drawn Carbon Steel

Corrosion Protection: Electroless nickel plating (5μm) on all wetted parts

II. Advanced Design & Operational Mechanics

2.1 Direct-Acting Control System

Unlike pilot-operated regulators, our direct-acting design eliminates external sensing lines through:

Monolithic Pressure Balancing Chamber

120cm² effective diaphragm area

Zero-friction graphite-coated stem

Dual-coil spring cartridge (parallel load configuration)

Proprietary Flow Dynamics

Venturi-optimized orifice (patent pending) reduces turbulence

Linear flow coefficient (Cv) of 22 at 0.56MPa

Pressure recovery ratio > 92%

2.2 Precision Adjustment System

Field technicians configure pressure via:

Calibrated T-handle Assembly

1 full rotation = 0.07MPa adjustment

Torque-limited safety stop

IP66-rated environmental seal

Fail-Safe Positioning

Spring-loaded poppet defaults to closed position

Redundant O-ring stem seals (Viton® FKM)

2.3 Maintenance-Optimized Construction

Modular Cartridge System: Replace seals without line disconnection

Inspectable Orifice: Transparent polycarbonate cover

Test Points: 1/8" NPT gauging ports upstream/downstream

III. Industrial Applications & Integration

3.1 Energy Sector Implementation

Natural Gas Distribution:

City gate stations pressure reduction (1.72MPa → 0.28MPa)

CNG mother station regulation

Biogas upgrading plant controls

LPG Infrastructure:

Bulk storage terminal vaporization control

Cylinder filling manifold regulation

3.2 Manufacturing & Process Industries

Combustion System Management:

Regenerative thermal oxidizers (RTOs)

Aluminum melting furnaces (500+ Nm³/h demand)

Ceramic kiln burner trains

Specialized Gas Applications:

Food processing CO2 injection

Semiconductor hydrogen delivery

Pharmaceutical nitrogen blanketing

3.3 Commercial Infrastructure

District Energy Systems:

Campus steam plant fuel control

Hospital central boiler regulation

High-Risk Environments:

Automotive paint shops

Aircraft hangar heating

IV. Installation & Performance Data

4.1 Mechanical Integration Guidelines

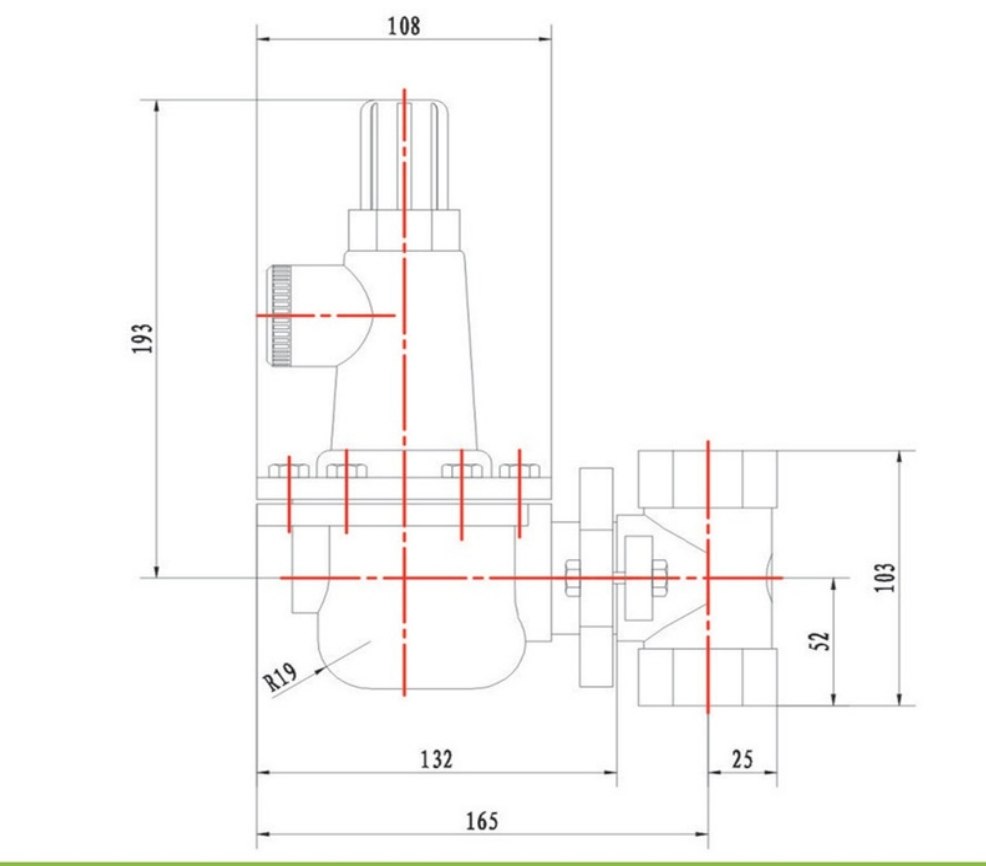

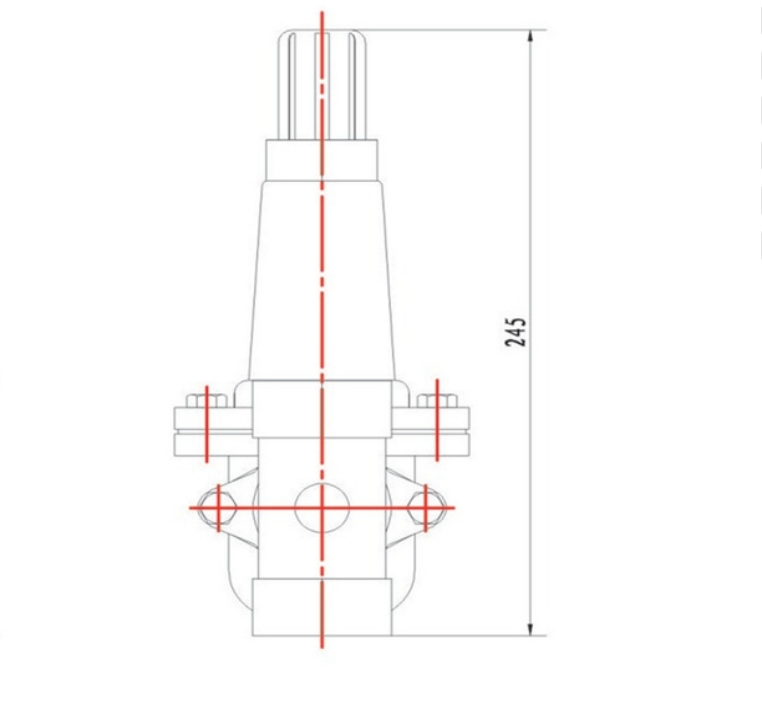

| Parameter | DN25 Configuration | DN50 Configuration |

|---|---|---|

| Pipe Engagement | 19mm minimum | 38mm minimum |

| Torque Specification | 120 N·m | 285 N·m |

| Flow Direction | Unidirectional (arrow-marked) | |

| Orientation | Vertical ±15° tolerance | |

| Purge Procedure | 10x volume displacement at 0.25MPa |

4.2 Certified Performance Curves

Flow-Pressure Characteristic:

0.5% droop at 50% capacity (vs. industry average 3%)

<0.01MPa lockup pressure

Temperature Compensation:

-0.008% setting change/°C between -20°C~60°C

Verified per EN 334:2018

4.3 Compliance & Certification

International Standards:

ISO 10533 Class AC10

EN 88-1:2011+A1:2016

ASME B31.1 Power Piping

Explosion Safety: ATEX Cat. 3G (2014/34/EU)

Material Certifications: PED 2014/68/EU Annex I

V. Value Engineering & Lifecycle Analysis

5.1 Operational Economics

Energy Savings: 7-12% reduced compressor workload vs. conventional regulators

Maintenance Interval: 5-year service cycle

Mean Time Between Failure (MTBF): 190,000 hours

5.2 Comparative Advantage

| Feature | Industry Standard | RTZ Series | Improvement |

|---|---|---|---|

| Adjustment Resolution | ±0.05MPa | ±0.01MPa | 500% |

| Cold Start Reliability | -10°C minimum | -20°C operational | 100% |

| Diaphragm Service Life | 3 years | 8 years | 267% |

| Overpressure Recovery | 25 seconds | 3.8 seconds | 658% |

5.3 Sustainability Profile

Leakage Rate: <0.001% Vn at SG15 (vs. ISO 15848 CO2 allowance)

Recyclability Index: 92% metal content (ISO 22628)

Carbon Footprint: 18.7 kg CO2e per unit (cradle-to-gate)

VI. Technical Support & Service

Digital Twin Integration: IoT-ready with 1/4" NPT sensor port

Global Certification Support:

CRN registration (Canada)

PED Category II modules

GOST-R (Eurasian compliance)

Onsite Calibration: NIST-traceable test equipment