- Home

- >

- News

- >

- Company news

- >

News

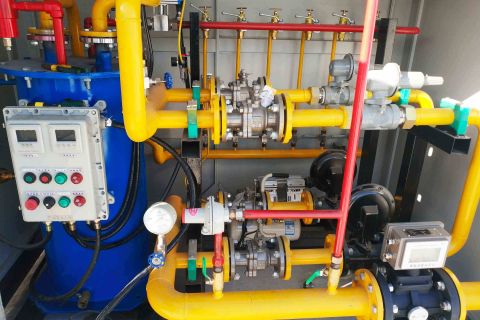

The company’s CNG Pressure Regulation Skid is designed to optimize the delivery of compressed natural gas from transport vehicles to end-use systems with precision and safety. The process begins as CNG enters the skid through a high-efficiency filter, ensuring the removal of contaminants that could affect downstream equipment. A ball valve and emergency shut-off valve provide an additional layer of control and safety, allowing for immediate isolation in case of an emergency.

The global energy landscape is undergoing a significant transformation, driven by the imperative to balance growing energy demands with environmental sustainability. Within this context, Liquefied Natural Gas (LNG) has emerged as a critical transitional fuel, and the infrastructure that supports its import, storage, and distribution—particularly LNG receiving terminals in ports—is becoming increasingly vital.

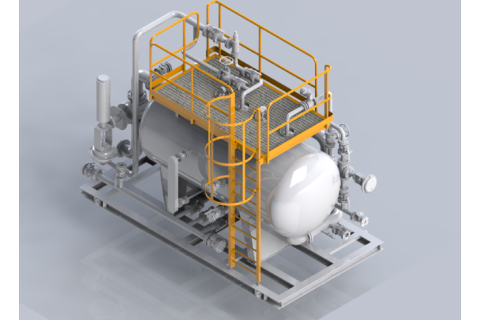

The Multi-Effect Skid-Mounted Plate Evaporator is an advanced industrial solution designed for high-efficiency concentration, crystallization, and separation processes. As depicted in the image, this system integrates multiple effects into a single, compact skid-mounted unit, constructed primarily from corrosion-resistant stainless steel to ensure durability and compliance with stringent industrial standards.

Traditional pipeline welding processes are plagued by complexity, high costs, and quality dependencies on manual skills. However, innovative approaches like "standardized prefabricated components + welding-free techniques" are transforming the industry. Among these, prefabricated sleeve quick-connect technology stands out, enabling rapid on-site assembly by simply inserting pipes and securing clasps. This method not only boosts efficiency by over 30% but also eliminates post-weld anti-corrosion treatments while offering superior resistance to stretching and vibration compared to traditional welding.

As global temperatures soar, energy infrastructure faces unprecedented challenges. Gas skid systems—pre-engineered, modular units for gas processing and distribution—are proving indispensable in hot climates. Recent deployments in Saudi Arabia’s 50°C desert environments and Australia’s Outback demonstrate how these systems outperform traditional setups. Equipped with AI-driven thermal regulation and corrosion-resistant materials, modern gas skids reduce downtime by 40% while maintaining operational stability, according to a 2023 DNV GL industry report.

Shanghai, China – Shanghai Shenqi Machinery Equipment Co., Ltd., a leading manufacturer specializing in gas pressure regulating skids, prefabricated pipelines, and skid modules, has announced the successful relocation of its operations to a state-of-the-art production facility. The move, which includes significant investments in advanced machinery and expanded production lines, underscores the company’s commitment to meeting growing global demand for its innovative energy infrastructure solutions.

Liquefied Natural Gas (LNG) has emerged as a clean, efficient, and versatile energy source for industries and transportation sectors. For LNG fueling stations, proper pre-cooling and systematic operational procedures are critical to ensure safety, efficiency, and compliance with international standards. This article outlines the detailed LNG refueling process, focusing on skid-mounted equipment setup, pre-cooling steps, and valve management protocols. Whether you’re a technician, plant operator, or fleet manager, understanding these steps will help optimize operations and minimize risks.

In a significant stride toward advancing global chemical processing infrastructure, [Your Company Name] has successfully delivered a cutting-edge modular chemical pump skid system to international clients, marking a milestone in engineering excellence and operational reliability. Designed to meet stringent international standards, this skid-mounted solution exemplifies innovation, adaptability, and resilience in addressing complex industrial challenges.

In the realm of modern energy solutions, GAS PRESSURE REGULATING SKIDS (GPS) play a pivotal role in optimizing the use of gas-based systems, such as those found in homes and industrial facilities.

Fuel oil separators encountering problems may show signs such as: Poor Separation: If the oil from the engine contains gas bubbles or excessive air content, it indicates a failure in separation. Examine for leaks between the tank and delivery line by checking the filter cover. A lack of oil or slow level decline may suggest a leak. Afterward, inspect the separator itself.