Design and Function of LNG Skid Modules

2026-01-27 17:17Design and Function of LNG Skid Modules

The Core Purpose and Design Philosophy of LNG Skid Modules

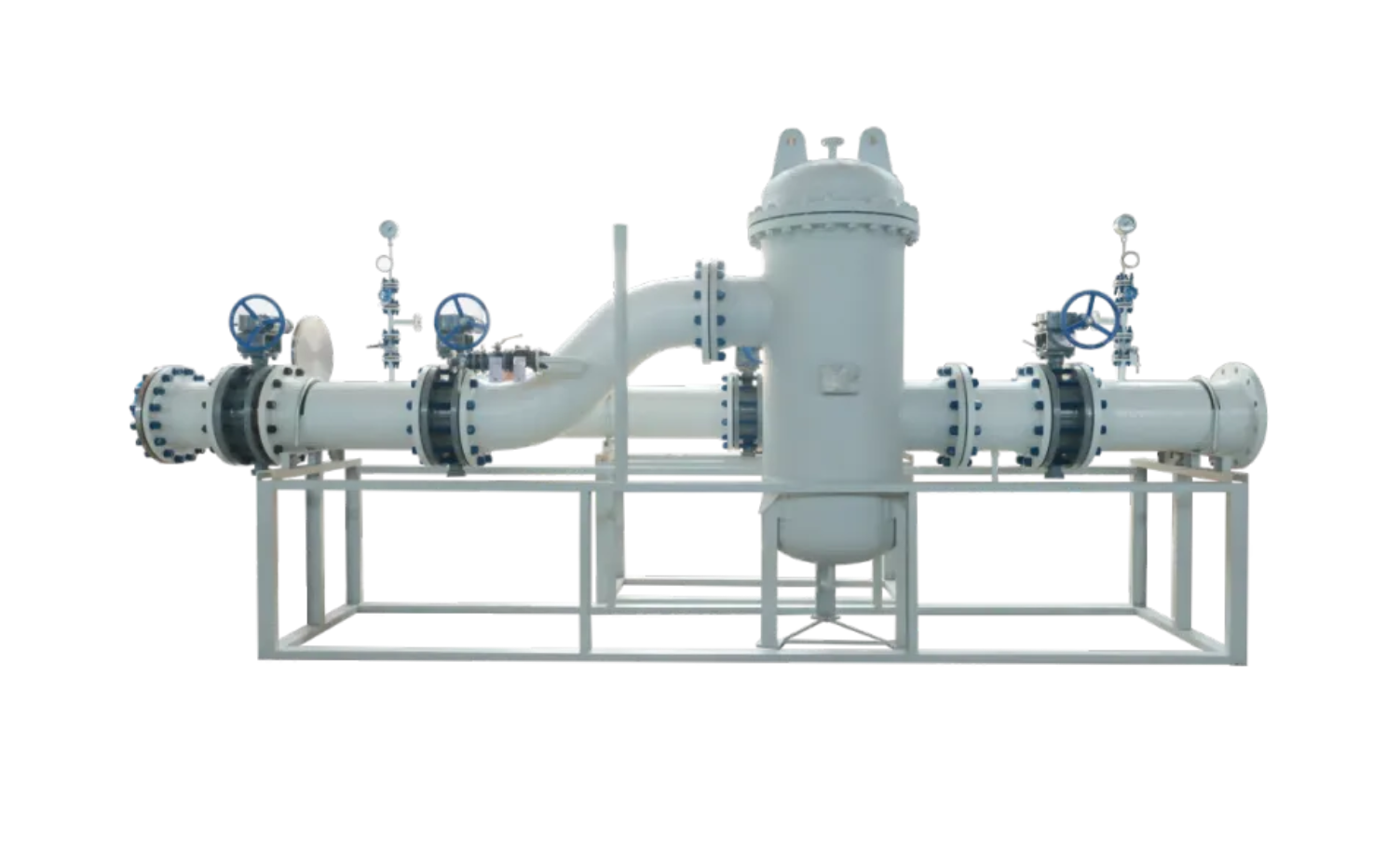

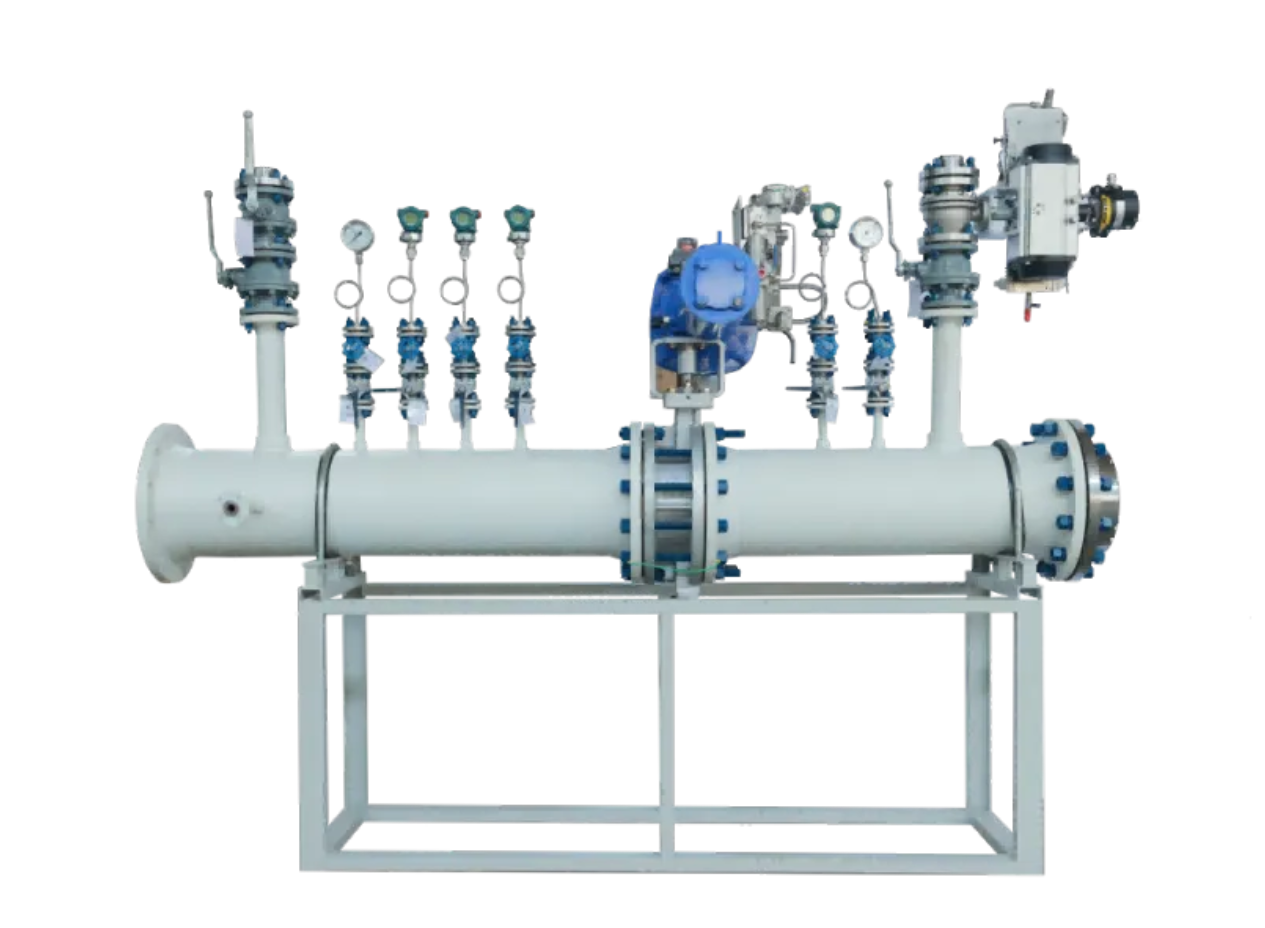

LNG (Liquefied Natural Gas) skid modules are highly specialized, self-contained processing units engineered to perform specific functions within the larger LNG value chain, from liquefaction and transportation to regasification and end-use applications. The fundamental design philosophy behind these modules is modularization, which involves integrating complex process equipment—such as heat exchangers, pumps, vaporizers, valves, and sophisticated control systems—onto a single, compact steel frame or within a containerized enclosure. This approach, championed by specialized manufacturers like Shanghai Shenqi Machinery, shifts complex fabrication and assembly from the challenging and often remote field environment to a controlled factory setting. The primary functional objective is to ensure the safe, efficient, and reliable handling of LNG, which is stored at cryogenic temperatures as low as -162°C (-260°F). The design must therefore account for extreme thermal contraction, material brittleness, and stringent safety standards, resulting in a robust plug-and-play solution that significantly reduces on-site risks and installation time.

Key Functional Processes in LNG Skid Modules

The function of an LNG skid module is dictated by its specific application within the supply chain. Common types include LNG vaporization skids, which are critical for regasification. These skids use heat sources (e.g., open-rack vaporizers using seawater, submerged combustion vaporizers, or ambient air vaporizers) to convert the cryogenic liquid back into gaseous natural gas for pipeline distribution. Another vital type is the LNG pumping skid, which houses high-pressure cryogenic pumps to boost the pressure of LNG for loading into transport tanks or for sending into the vaporizers. BOG (Boil-Off Gas) handling skids are also essential, designed to manage the natural evaporation of LNG in storage tanks by re-liquefying the gas or compressing it for use as fuel. Regardless of the specific function, each module relies on precision instrumentation and control, with automated systems continuously monitoring parameters like temperature, pressure, and flow to ensure optimal and safe performance, making them an integrated process unit.

Engineering for Cryogenic Service and Safety

The engineering and fabrication of LNG skid modules demand exceptional expertise in cryogenic material selection and safety-centric design. Standard carbon steel becomes brittle at LNG temperatures, so materials like stainless steel (e.g., 304/316L) and aluminum alloys are mandatory for all wetted parts to maintain toughness and integrity. The design incorporates special considerations for thermal insulation, utilizing advanced materials such as polyurethane foam (PUF) or vacuum jacketed piping to minimize heat ingress and prevent excessive BOG generation. Safety systems are paramount and are built with multiple layers of protection. These include emergency shutdown (ESD) valves, pressure safety valves (PSVs) to prevent overpressure, gas detection systems to identify leaks, and comprehensive fire protection measures. Manufacturers like Shanghai Shenqi Machinery leverage their cryogenic experience to ensure that every weld, component placement, and system integration meets the highest international standards, resulting in a pre-tested module that arrives on-site ready for efficient connection and commissioning.

In summary, LNG skid modules represent the pinnacle of modular engineering, combining precise design with robust functionality to handle one of the most challenging industrial substances. By condensing complex processes into pre-assembled, factory-tested packages, they deliver unparalleled reliability, safety, and cost-effectiveness, making them indispensable for the modern LNG industry.