Top 5 Benefits of Using a Prefabricated Pipeline System

2026-01-26 17:10Top 5 Benefits of Using a Prefabricated Pipeline System

Significant Time and Cost Savings

The most immediate benefit of a prefabricated pipeline system is the dramatic reduction in project timelines and overall costs. Unlike traditional stick-built methods where pipes are cut, welded, and assembled piece-by-piece on-site—a process highly susceptible to weather delays, logistical issues, and labor shortages—prefabrication occurs in a controlled factory environment. This allows for parallel processing, where pipeline modules are manufactured off-site by specialists like Shanghai Shenqi Machinery while site preparation (e.g., foundation work) happens simultaneously. This approach slashes construction schedules by up to 50% or more. Furthermore, factory-based fabrication minimizes material waste through precise cutting and planning, reduces the need for expensive on-site labor and supervision, and leads to lower overall project risk and cost, delivering a faster return on investment (ROI) for owners.

Enhanced Quality Control and Superior Safety

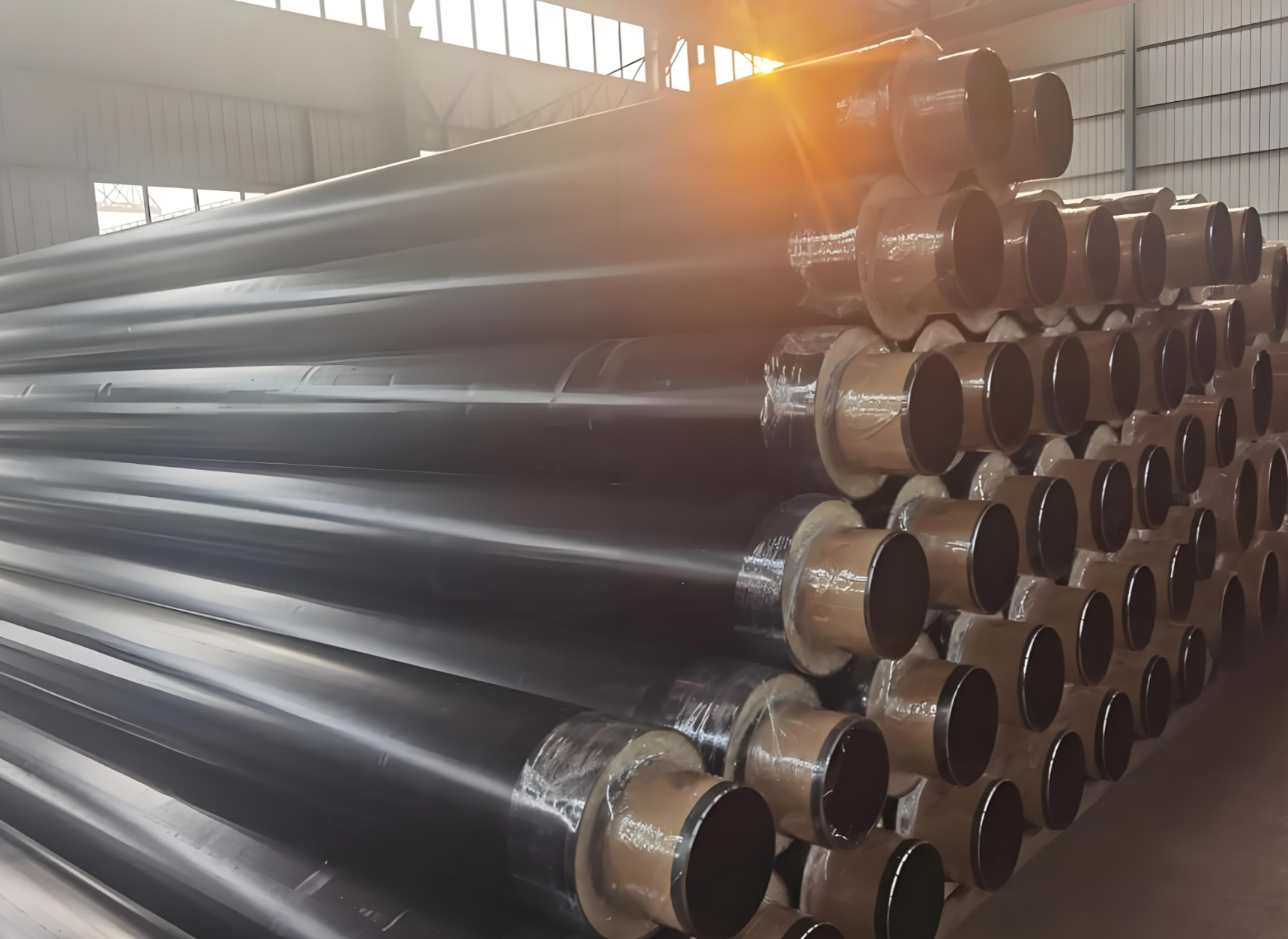

Prefabricated pipeline systems offer unparalleled quality assurance compared to field welding. In a factory setting, welding, coating, and assembly are performed under strict protocols by certified welders using advanced equipment, unaffected by adverse weather conditions like rain, wind, or dust that can compromise on-site weld integrity. Each module undergoes rigorous non-destructive testing (NDT), such as X-ray and ultrasonic inspection, and is subjected to hydrostatic testing to ensure leak-free performance before it ever leaves the facility. This controlled environment also translates to a much safer project. By shifting the majority of labor from a congested, potentially hazardous construction site to an organized factory floor, the risk of on-site accidents is significantly reduced. This proactive approach to safety management ensures a higher quality, more reliable end product that complies with international standards like ASME and API.

Improved Consistency, Precision, and Flexibility

Modular construction ensures exceptional consistency and precision across the entire pipeline system. Since components are built using specialized jigs and fixtures with digital templates, every prefabricated spool and module is identical, eliminating the dimensional variances common in field measurements and fabrication. This precision engineering is crucial for complex systems involving intricate piping arrangements, instrumentation, and supports, guaranteeing perfect fit-up during installation. Additionally, prefabricated systems offer remarkable design flexibility. Modules can be designed for easy future expansion or modification. If a process change is required, specific modules can be modified or replaced in the factory with minimal disruption to the overall operation, a stark contrast to the costly and time-consuming shutdowns typically needed for altering traditional stick-built pipelines.

In conclusion, the adoption of prefabricated pipeline systems is a strategic decision that delivers tangible advantages in speed, cost, quality, safety, and adaptability. For companies like Shanghai Shenqi Machinery, specializing in these systems means providing clients with a smarter, more efficient, and more reliable solution for their critical industrial infrastructure needs, ultimately driving project success and long-term operational excellence.