The Role of Automation in Smart Skid Modules

2026-01-31 18:15The Role of Automation in Smart Skid Modules

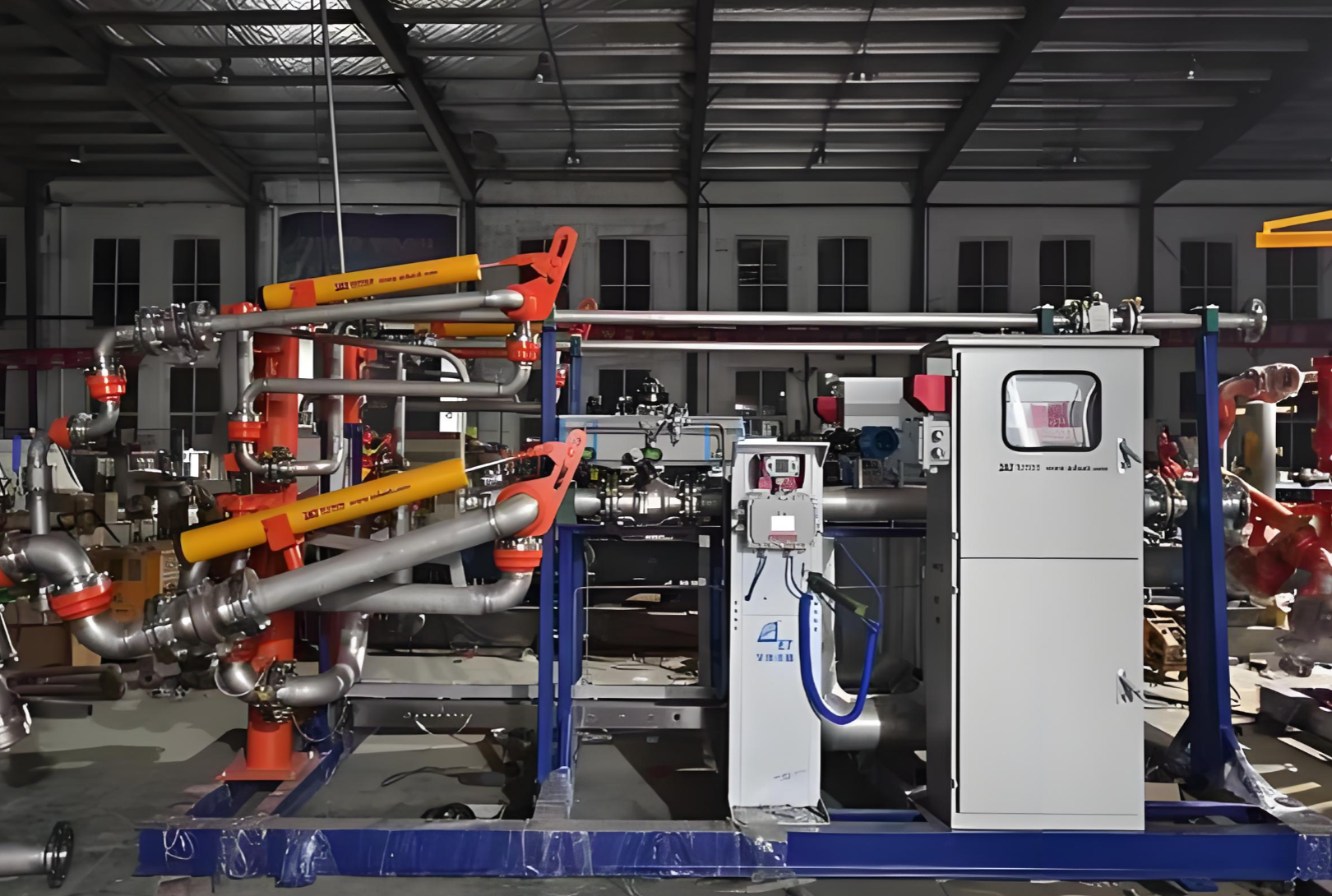

From Manual Operation to Intelligent Control

The evolution of skid-mounted equipment into smart skid modules is fundamentally driven by the integration of advanced automation. Traditional skids were primarily mechanical assemblies, requiring constant manual monitoring and adjustment of valves, pumps, and pressures. In contrast, smart skids are equipped with a comprehensive suite of instrumentation and control systems. This includes sensors for measuring pressure, temperature, flow, and level; automated control valves and actuators; and a centralized Programmable Logic Controller (PLC). The PLC acts as the brain of the skid, executing pre-programmed logic to maintain optimal process conditions without human intervention. This transition from manual to automated control is the first critical step, enabling not just remote operation but also the continuous, precise, and reliable functioning of complex processes like chemical injection, gas regulation, or pumping, forming the foundational layer of intelligence.

Data Acquisition, Analysis, and Predictive Capabilities

The true "smart" nature of these modules extends beyond basic control to sophisticated data acquisition and analysis. The array of sensors on a smart skid continuously generates a stream of operational data. This data is not only used for real-time control but is also logged, stored, and analyzed by the system. Modern smart skids often feature Supervisory Control and Data Acquisition (SCADA) interfaces or Human-Machine Interfaces (HMIs), providing operators with intuitive visualization of the entire process. More importantly, this data enables predictive maintenance strategies. By analyzing trends in parameters like vibration, motor current, or pressure differentials, the system can predict potential equipment failures—such as pump bearing wear or valve blockage—before they occur. This allows maintenance to be scheduled proactively, preventing unplanned downtime and maximizing asset utilization, thereby transforming operational management from reactive to proactive and data-driven.

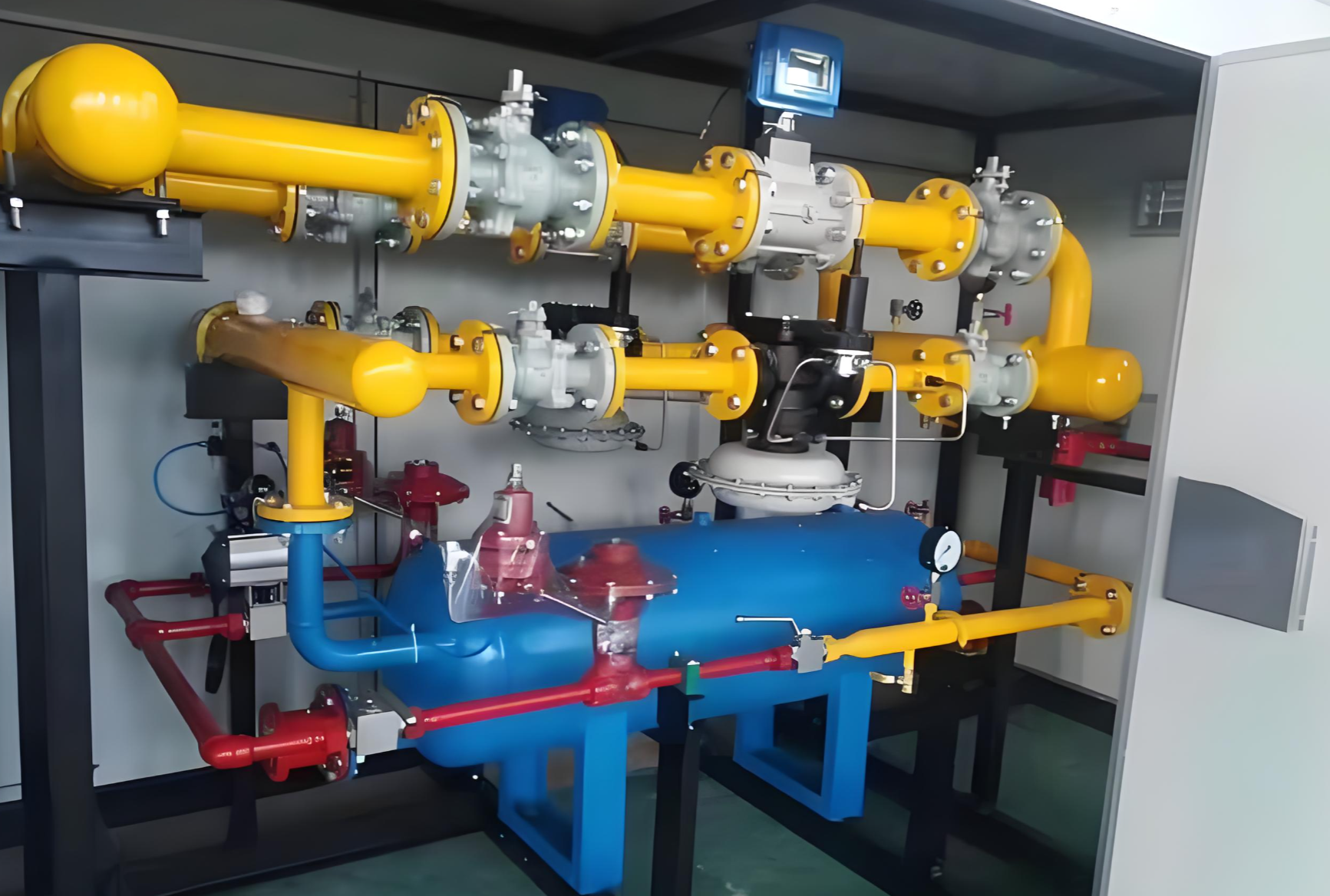

Enhancing Safety, Integration, and Remote Accessibility

Automation is a critical enabler for enhanced safety and seamless system integration. Smart skid modules are designed with multiple layers of protection, including automated safety interlocks and Emergency Shutdown (ESD) systems. In the event of a detected anomaly—such as a pressure surge, gas leak, or high temperature—the PLC can automatically initiate a safe shutdown sequence, isolating sections of the process to prevent accidents. Furthermore, the standardized communication protocols (e.g., Modbus, PROFIBUS, Ethernet/IP) used in these skids allow for effortless integration with larger plant control systems. Finally, the capability for remote monitoring and control is a game-changer. Authorized personnel can access the skid's operational data and control functions from a central control room or even via secure internet connections from anywhere in the world. This not only reduces the need for physical presence in potentially hazardous areas but also allows for expert support and troubleshooting from off-site, ensuring optimal performance and safety 24/7.

In summary, automation is the cornerstone that transforms conventional skids into intelligent, high-performance assets. By embedding control, data analytics, and connectivity, smart skid modules deliver unprecedented levels of operational efficiency, predictive maintenance, safety, and remote manageability, representing the future of industrial process equipment.