The Role of Chemical Injection Skids in Enhancing Oil & Gas Production

2026-01-23 13:19The Role of Chemical Injection Skids in Enhancing Oil & Gas Production

Ensuring Flow Assurance and Protecting Critical Infrastructure

The primary role of Chemical Injection Skids (CIS) is to safeguard production continuity by preventing blockages and corrosion within the well and pipeline network. In oil and gas production, flowing streams are prone to challenges such as hydrate formation, scale deposition, wax precipitation, and paraffin buildup, all of which can severely restrict or completely halt flow. Furthermore, produced fluids often contain corrosive elements like carbon dioxide (CO₂) and hydrogen sulfide (H₂S) that aggressively attack metal pipes and equipment. The CIS is engineered to combat these issues proactively. It precisely injects specialized chemicals—such as scale inhibitors, corrosion inhibitors, hydrate suppressants, and paraffin dispersants—directly into the flow line or wellhead. By maintaining a precise dosage of these chemicals, the skid ensures unimpeded flow of hydrocarbons, protects the integrity of multi-million-dollar infrastructure from degradation, and prevents costly, unplanned shutdowns for remediation, thereby directly maximizing uptime and asset lifespan.

Optimizing Reservoir Recovery and Enhancing Production Efficiency

Beyond basic protection, Chemical Injection Skids play a strategic role in enhancing hydrocarbon recovery from the reservoir. Techniques such as Enhanced Oil Recovery (EOR) rely on the precise injection of chemicals into the reservoir to alter the physical or chemical properties of the fluids and the reservoir rock itself. For example, polymers can be injected to increase the viscosity of the injection water, improving its sweep efficiency and displacing more oil. Surfactants can be injected to reduce the interfacial tension between oil and water, mobilizing trapped residual oil. The CIS provides the high-pressure, precise, and reliable injection capability required for these sophisticated processes. By enabling finer control over reservoir dynamics, these skids help unlock additional reserves that would otherwise remain unrecoverable, thereby significantly boosting the overall recovery factor and maximizing the economic value of the field.

Providing Precision, Reliability, and Integration in Demanding Environments

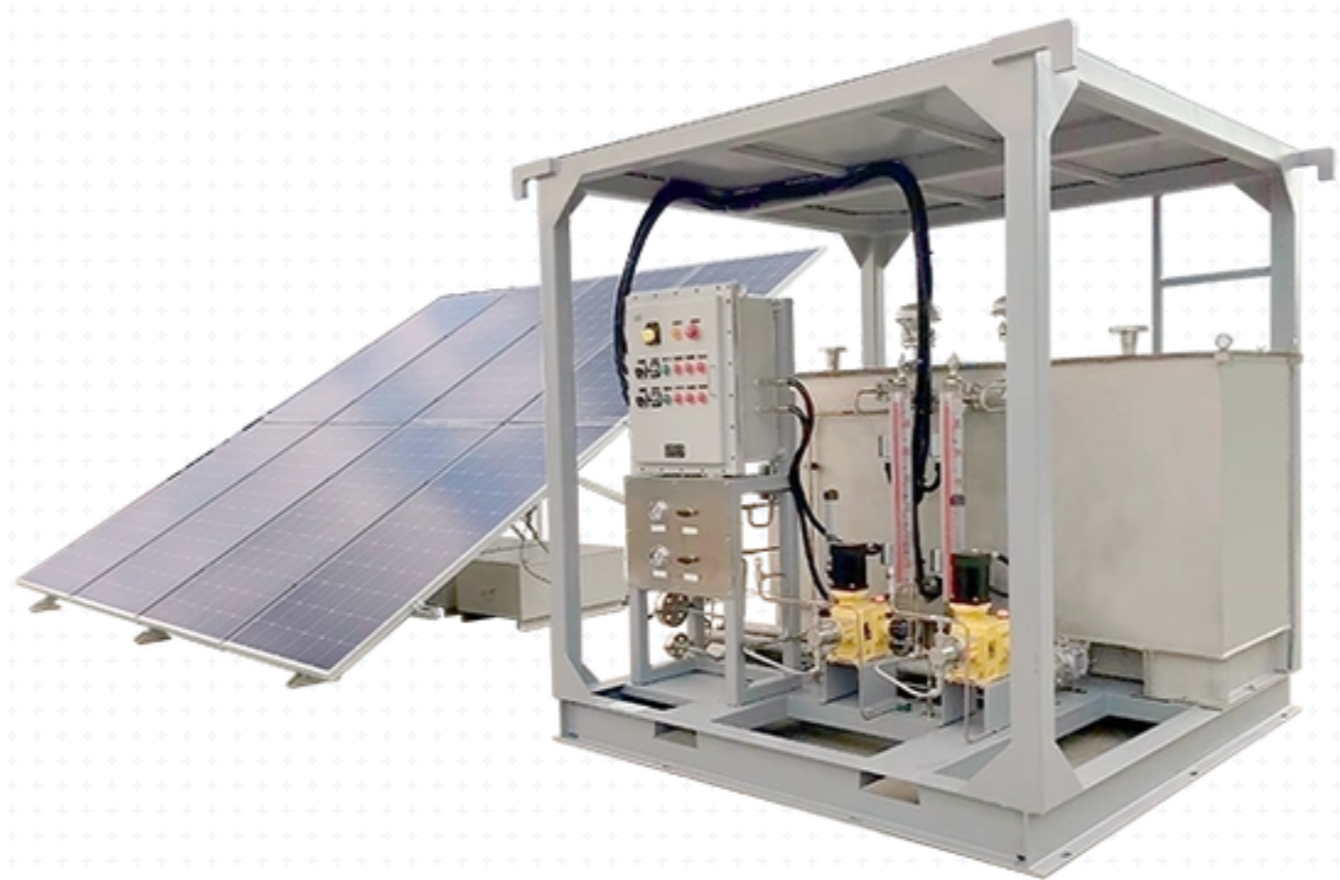

The effectiveness of chemical injection is entirely dependent on the precision and reliability of the skid itself. These units are engineered to operate autonomously and flawlessly in remote, harsh, and potentially explosive environments, both onshore and offshore. A typical skid integrates chemical storage tanks, high-accuracy metering pumps, filters, pressure gauges, and a sophisticated control system. The system allows for precise adjustment of injection rates to match real-time production data, ensuring optimal chemical usage—avoiding under-dosing (which risks failure) and over-dosing (which incurs unnecessary cost). For operators, the skid-mounted approach offers a significant advantage: it arrives as a pre-assembled, pre-tested, and ready-to-connect package. This plug-and-play nature, a core capability of suppliers like Shanghai Shenqi Machinery, drastically reduces on-site installation time and complexity, ensures faster commissioning, and guarantees performance through comprehensive Factory Acceptance Testing (FAT), providing a complete and dependable solution.

In essence, Chemical Injection Skids are indispensable assets in modern oil and gas production. They function as a vital protective system for flow assurance and infrastructure integrity, a strategic tool for enhancing ultimate recovery, and a benchmark of engineering precision and operational reliability. By delivering chemicals in a controlled, accurate, and dependable manner, these skids directly contribute to safer, more efficient, and more profitable operations throughout the entire production lifecycle.