Why Custom-Engineered Skids Beat Field Assembly Every Time

2026-01-04 14:15Why Custom-Engineered Skids Beat Field Assembly Every Time

Faced with a new project, the "do-it-yourself" approach of field-assembling components from multiple vendors can seem cost-effective. However, this path is fraught with hidden risks, delays, and compromises. This article explains why opting for a custom-engineered skid from an integrated supplier like Shanghai Shenqi is the smarter, safer, and more economical choice every time.

Beyond the Initial Price Tag

The apparent savings of a DIY field assembly often vanish when total cost of ownership is considered. This fragmented approach involves managing multiple suppliers, each with their own lead times, documentation, and interfaces. This creates a logistical nightmare, leading to project delays as you coordinate between pipe fabricators, valve suppliers, instrumentation vendors, and civil contractors. The lack of single-point responsibility means finger-pointing is inevitable when integration issues arise, causing costly troubleshooting and downtime. Furthermore, field welding and assembly are subject to weather delays, variable quality depending on crew skill, and potential rework due to on-the-fly design changes. A custom-engineered skid consolidates all these elements into a single, turnkey package from a responsible provider like Shanghai Shenqi, ensuring a fixed price, a guaranteed timeline, and a single point of accountability, ultimately saving significant time, money, and stress.

Integrated System Testing vs. On-Site Guesswork

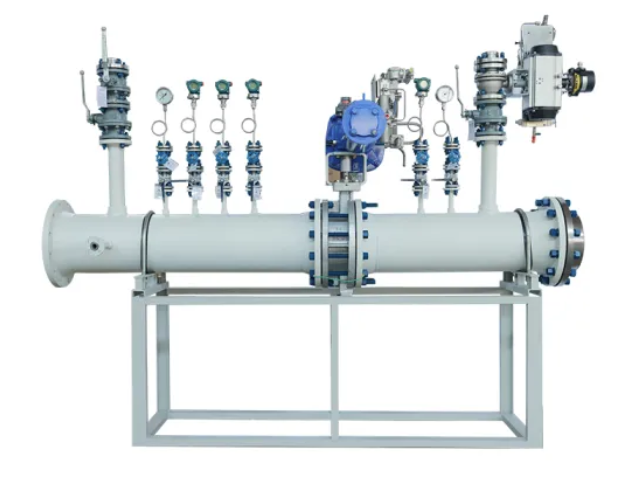

The most critical difference lies in validation. With field assembly, the entire system is operated together for the first time during commissioning. This is a high-stakes gamble where component incompatibilities, design flaws, or installation errors can lead to catastrophic failures, prolonged startup delays, and significant safety risks. In contrast, a custom skid undergoes rigorous Factory Acceptance Testing (FAT). At Shanghai Shenqi's facility, the complete, fully piped and wired skid is activated under simulated operational conditions. Every pump, valve, sensor, and safety interlock is tested to function as an integrated system. This process guarantees performance before the unit ever leaves the factory. Clients can witness the FAT, providing unparalleled confidence and peace of mind. This eliminates the guesswork and uncertainty of on-site commissioning, transforming a potentially chaotic startup into a predictable, plug-and-play operation, and ensuring immediate operational readiness upon installation.

A Partner vs. a Pile of Parts

A skid is a long-term asset, and its value extends far beyond day one. A field-assembled system lacks unified documentation, with manuals, P&IDs, and certificates scattered across vendors. This makes future maintenance, troubleshooting, and expansion incredibly complex. Who do you call when a problem arises? A custom skid from a single-source provider comes with a complete, as-built documentation package and, most importantly, a single point of contact for technical support, spare parts, and warranty claims. Manufacturers like Shanghai Shenqi design for serviceability, with clear access points and standardized components that simplify maintenance. This partnership approach ensures the asset's longevity, optimizes its lifecycle cost, and provides operational continuity. The DIY approach leaves you with a pile of parts and responsibility; the custom-engineered skid provides a supported, reliable solution for the entire lifespan of the equipment.

The "DIY mistake" is a false economy that trades short-term perceived savings for long-term risk, uncertainty, and higher total cost. A custom-engineered skid is not just a product; it is a comprehensive solution that delivers guaranteed performance, single-source accountability, and enduring reliability. By partnering with an expert like Shanghai Shenqi, you invest not only in equipment but in peace of mind, ensuring your project's success from conception through decades of operation.