News

Gas pressure regulating stations (or cabinets) are critical components in natural gas distribution systems, ensuring that gas is delivered at safe and stable pressures for various applications, including industrial, commercial, and residential use. These stations consist of filters, valves, pressure regulators, heat exchangers, and safety devices (such as safety valves and emergency shut-off valves) to control and stabilize gas pressure before it reaches end-users.

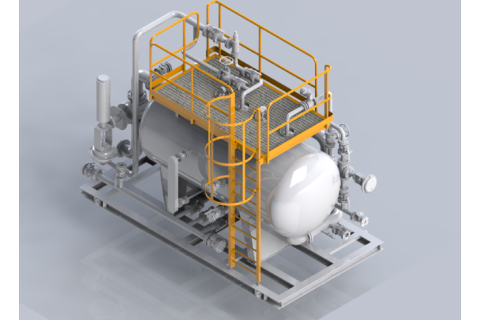

The company’s CNG Pressure Regulation Skid is designed to optimize the delivery of compressed natural gas from transport vehicles to end-use systems with precision and safety. The process begins as CNG enters the skid through a high-efficiency filter, ensuring the removal of contaminants that could affect downstream equipment. A ball valve and emergency shut-off valve provide an additional layer of control and safety, allowing for immediate isolation in case of an emergency.

The global energy landscape is undergoing a significant transformation, driven by the imperative to balance growing energy demands with environmental sustainability. Within this context, Liquefied Natural Gas (LNG) has emerged as a critical transitional fuel, and the infrastructure that supports its import, storage, and distribution—particularly LNG receiving terminals in ports—is becoming increasingly vital.

The Multi-Effect Skid-Mounted Plate Evaporator is an advanced industrial solution designed for high-efficiency concentration, crystallization, and separation processes. As depicted in the image, this system integrates multiple effects into a single, compact skid-mounted unit, constructed primarily from corrosion-resistant stainless steel to ensure durability and compliance with stringent industrial standards.

Traditional pipeline welding processes are plagued by complexity, high costs, and quality dependencies on manual skills. However, innovative approaches like "standardized prefabricated components + welding-free techniques" are transforming the industry. Among these, prefabricated sleeve quick-connect technology stands out, enabling rapid on-site assembly by simply inserting pipes and securing clasps. This method not only boosts efficiency by over 30% but also eliminates post-weld anti-corrosion treatments while offering superior resistance to stretching and vibration compared to traditional welding.

Modular gas regulation skids are no longer accessories but central nervous systems of modern energy networks. As your product data indicates (models 6829145/6829146), standardization doesn't inhibit innovation – it enables it. These systems' compactness, intelligence, and adaptability make them indispensable for the energy transition.

The Pig Launcher and Receiver Skid (Model 7506556) represents a quantum leap in pipeline maintenance technology. These integrated 1280x1280 mm modular units – like the one shown in your product list – are transforming how energy giants tackle corrosion prevention, efficiency optimization, and regulatory compliance. As pipelines age and environmental regulations tighten, skid-based pigging systems have seen 47% annual growth (Global Pipeline Solutions Report 2025).

The Middle East, synonymous with vast hydrocarbon reserves, is experiencing a dynamic shift within its energy landscape. Alongside its role as a global LNG export powerhouse, a significant and growing demand for modular LNG skid systems is emerging across the region. These pre-engineered, transportable solutions are uniquely positioned to address several critical energy priorities for Middle Eastern nations. For suppliers and service providers, understanding this specific demand is key to unlocking substantial business opportunities.

Liquefied Natural Gas (LNG) has emerged as a critical energy source in the global transition toward cleaner and more efficient fuel alternatives. Its versatility, environmental benefits, and cost-effectiveness make it an ideal solution for diverse industries. Among the innovative technologies enabling its widespread adoption, LNG skid-mounted systems stand out as portable, user-friendly, and highly adaptable solutions. This article explores the multifaceted applications of LNG skid-mounted systems, as outlined in the provided technical documentation, highlighting their role in industrial, commercial, and infrastructural settings.