- Home

- >

- Products

- >

- Surge Relief Skid

- >

Surge Relief Skid

Surge Relief Skid, a crucial solution for liquid transportation in various industrial applications. This advanced equipment is designed to safeguard your pipelines, equipment, and personnel from the harmful effects of surge pressures.

- SQ

- China

- 15days

- 30000

- Information

1. Product Overview

Our Surge Relief Skid is a skid - mounted, integrated system that serves as a reliable safeguard in liquid transportation pipelines. It is equipped with high - quality anti - surge valves and is an essential part of a comprehensive Anti - Surge System. The skid is designed to handle the sudden and often dangerous pressure surges that can occur during liquid transfer processes, such as those in industrial pipelines, storage terminals, and marine loading and unloading operations.

2. Key Features and Advantages

2.1 High - Quality Materials and Robust Construction

Constructed with top - grade materials, our Surge Relief Skid is built to last. The main body of the skid and its associated pipelines are made from high - strength carbon steel, low - temperature carbon steel, alloy steels, or stainless steels, depending on the specific application requirements. This ensures excellent resistance to corrosion, high - pressure conditions, and the harsh environments often encountered in industrial settings. For example, in a petrochemical plant where aggressive chemicals are transported, the stainless - steel components of the skid can withstand the corrosive effects of the liquids, providing long - term reliability.

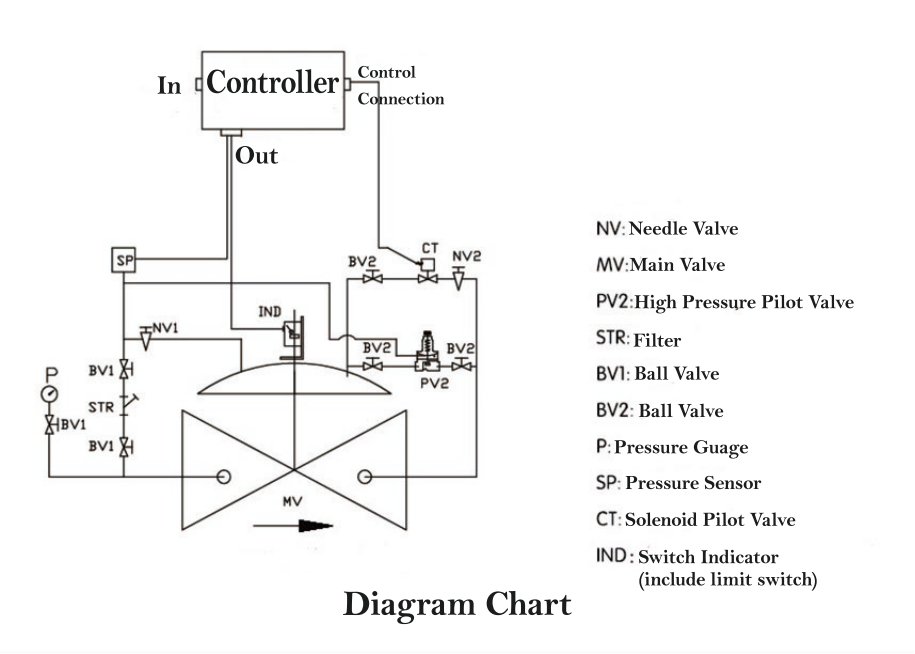

2.2 Fast Response and Precise Pressure Control

The anti - surge valves integrated into the skid are designed to have an exceptionally fast response speed. When a pressure surge is detected, the valves can quickly open or close to regulate the flow and pressure within the pipeline. This rapid response helps to prevent damage to the pipeline and equipment caused by excessive pressure. Moreover, the valves offer linear control characteristics, allowing for precise adjustment of the pressure relief. This ensures that the pipeline operates within the safe pressure range, reducing the risk of leaks, ruptures, or other pipeline failures.

2.3 Modular and Skid - Mounted Design

The modular construction of our Surge Relief Skid offers numerous benefits. It is pre - assembled in our factory, with all components carefully integrated onto a single skid. This skid - mounted design simplifies installation at the site. Once delivered, it can be quickly positioned and connected to the existing pipeline system, minimizing on - site installation time and labor costs. Additionally, the modular nature allows for easy maintenance and upgrades. If a component needs to be repaired or replaced, it can be easily removed and swapped out without the need for extensive re - engineering or modification of the entire system.

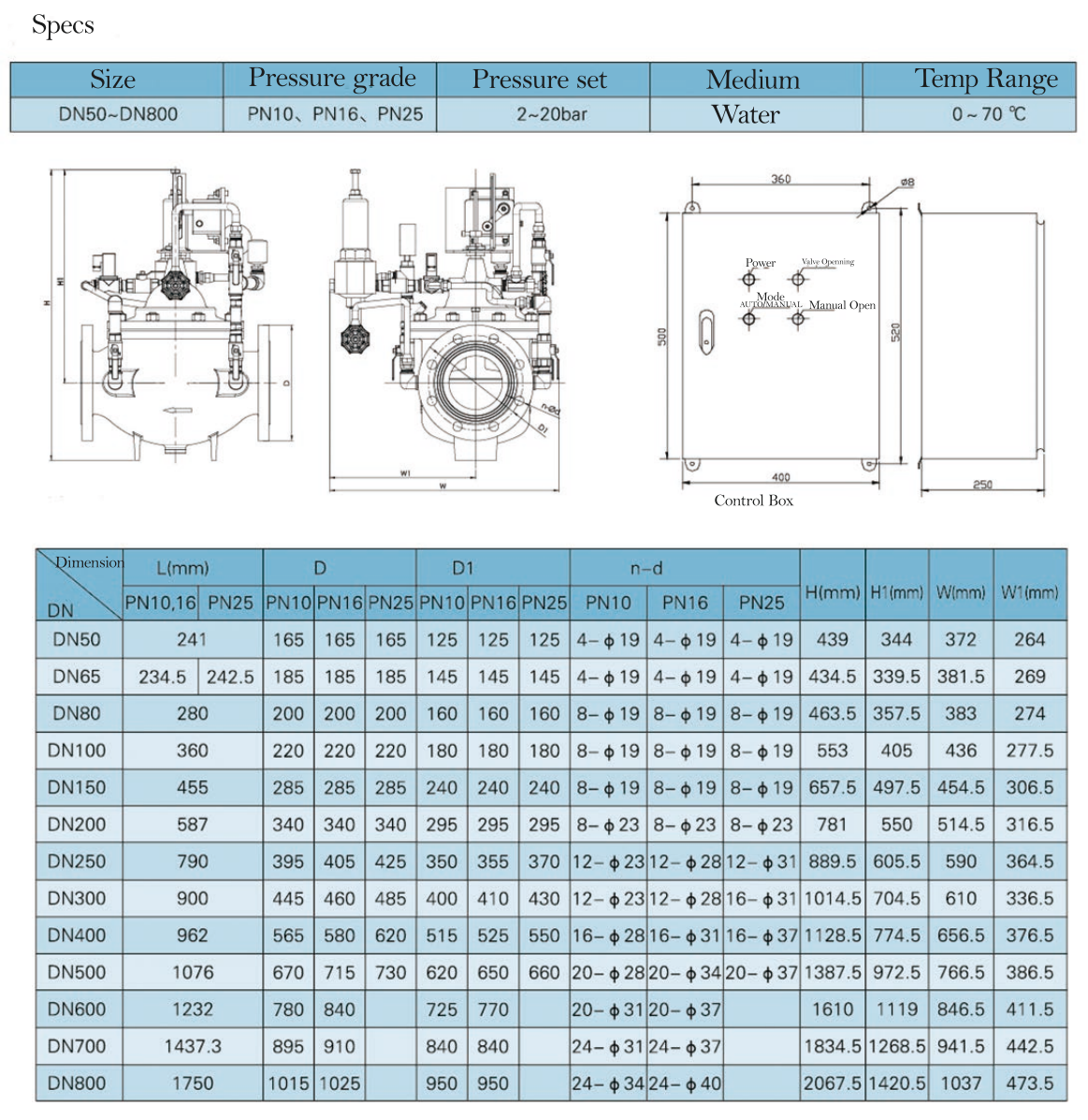

2.4 Customizable to Specific Requirements

We understand that each industrial application has unique requirements. Our Surge Relief Skid can be fully customized to meet your specific needs. Whether it's the size of the skid, the type of anti - surge valves, the pressure rating, or the end - connections, our engineering team can design a solution that is tailored to your pipeline system. For instance, if you have a pipeline with a specific diameter and pressure range, we can design the skid to match those parameters precisely, ensuring optimal performance.

2.5 High Flow Capacity

Our Surge Relief Skid is engineered to handle high - flow applications. It has a high flow capacity, which means it can quickly relieve excess pressure during a surge event without causing a significant disruption to the liquid flow. This is crucial in industries where continuous and efficient liquid transportation is essential, such as in oil and gas pipelines or large - scale chemical processing plants. The high - flow - coefficient design of the anti - surge valves enables them to pass large volumes of liquid, maintaining the integrity of the pipeline system during both normal and abnormal operating conditions.

2.6 Low Maintenance Requirements

Thanks to its high - quality construction and well - designed components, our Surge Relief Skid has low maintenance requirements. The anti - surge valves are designed with features such as balanced piston designs and no diaphragms or stuffing boxes, reducing the need for frequent maintenance and replacement of these parts. Additionally, the skid is equipped with easy - access panels and clear instructions for maintenance tasks, making it convenient for your maintenance staff to perform routine inspections and repairs. This helps to minimize downtime and ensure the continuous operation of your liquid transportation system.