Revolutionizing Pipeline Construction

2025-09-04 19:25Revolutionizing Pipeline Construction: The Rise of Prefabricated Quick-Installation Technologies

Introduction

Traditional pipeline welding processes are plagued by complexity, high costs, and quality dependencies on manual skills. However, innovative approaches like "standardized prefabricated components + welding-free techniques" are transforming the industry. Among these, prefabricated sleeve quick-connect technology stands out, enabling rapid on-site assembly by simply inserting pipes and securing clasps. This method not only boosts efficiency by over 30% but also eliminates post-weld anti-corrosion treatments while offering superior resistance to stretching and vibration compared to traditional welding.

1. The Limitations of Traditional Welding

Traditional on-site welding involves:

Time-consuming processes: Cutting, aligning, and welding pipes segment by segment.

High labor costs: Dependence on skilled welders and extensive manual labor.

Inconsistent quality: Vulnerable to environmental factors (e.g., weather, dust) and human error.

Additional steps: Post-weld anti-corrosion treatments and inspections further delay projects.

These challenges often lead to project delays, budget overruns, and safety risks, especially in complex industries like oil and gas or water treatment.

2. Prefabricated Quick-Installation Technology: How It Works

Core Components

Standardized Prefabricated Sleeves: Factory-produced sleeves with precision-engineered interfaces for seamless pipe connections.

Quick-Connect Mechanisms: Clamp-type or push-in designs using stainless steel shells and specialized rubber seals to ensure leak-proof connections.

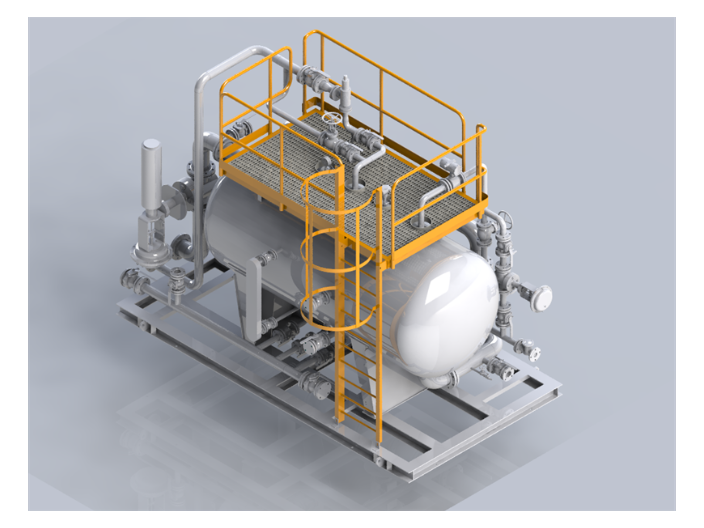

Modular Design: Pipes pre-assembled into modules (e.g., spools, skids) with integrated valves, fittings, and supports.

Installation Process

Factory Prefabrication: Pipes and components are cut, bent, and assembled in controlled environments using automated machinery.

Quality Testing: Modules undergo pressure tests, dimensional checks, and corrosion protection coating.

On-Site Assembly: Prefabricated modules are transported to sites and connected using quick-connect systems, requiring minimal tools and labor.

3. Key Advantages of Quick-Installation Technology

Efficiency Gains

30% Faster Installation: Reduced on-site labor and elimination of welding/curing time.

Parallel Workflows: Site preparation and factory prefabrication occur simultaneously, shortening project timelines.

Cost Savings

Lower Labor Costs: Reduced need for highly skilled welders.

Minimized Rework: Factory-quality control ensures precision, reducing errors and material waste.

Enhanced Quality and Safety

Superior Sealing: Rubber seals and clamp mechanisms provide vibration resistance and leak-proof performance.

Reduced On-Site Risks: Fewer hot works (e.g., welding) in hazardous environments.

Sustainability

Less Waste: Precise factory production reduces material scrap.

Energy Efficiency: Lower on-site energy consumption (e.g., no generators for welding equipment).

4. Applications Across Industries

Industry | Use Cases | Benefits |

|---|---|---|

Oil & Gas | Wellhead piping, transfer pipelines, offshore platforms | Corrosion resistance, rapid deployment in remote locations |

Water Treatment | Municipal water supply, drainage systems | Leak-proof connections, reduced maintenance |

HVAC | Industrial cooling/heating systems | Vibration resistance, easy modular upgrades |

Chemical Plants | Corrosive fluid transport | Compatibility with stainless steel/plastic pipes |

5. Future Trends and Innovations

Smart Integration: IoT sensors embedded in prefabricated modules for real-time monitoring of pressure and leaks.

Advanced Materials: Lightweight composites enhancing durability and corrosion resistance.

Automation: AI-driven design and robotic assembly further reducing human intervention.

Conclusion

Prefabricated quick-installation technologies represent a paradigm shift in pipeline construction, addressing the inefficiencies of traditional welding while delivering unmatched speed, cost savings, and reliability. For global industries seeking to optimize infrastructure projects, adopting these solutions is not just an option—it is a strategic imperative for the future.

Keywords: Prefabricated Pipelines, Quick-Connect Systems, Welding-Free Technology, Modular Construction, Pipeline Efficiency.