The Engineering Behind Natural Gas Measuring and Regulation Skids

2026-01-21 13:09The Engineering Behind Natural Gas Measuring and Regulation Skids

The Synergy of Measurement and Pressure Control

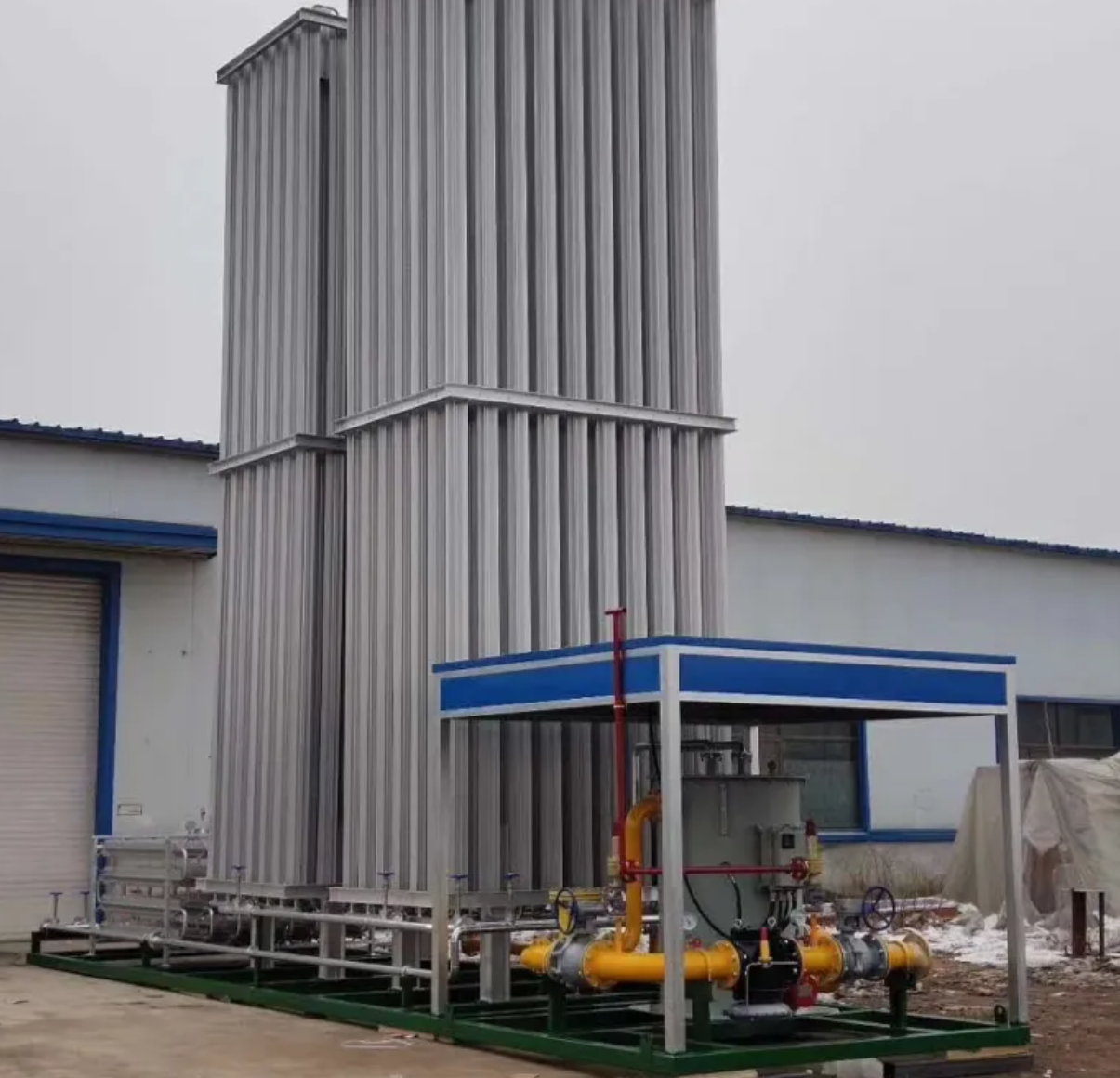

A Natural Gas Measuring and Regulation Skid is not merely an assembly of individual components; it is a meticulously engineered system where precision measurement and stable pressure regulation work in concert. The skid's architecture typically follows the process sequence: incoming gas first passes through a filter separator to remove particulates and liquids, protecting downstream equipment. It then flows through the metering run, which consists of a flow conditioner to eliminate flow profile distortions and a primary flow element, such as an orifice plate or ultrasonic flow meter, for highly accurate volumetric or mass measurement. Immediately following this, the pressure regulation system, comprising a high-capacity regulator and a monitor regulator as a fail-safe, takes over to reduce the gas pressure to the precise level required by the distribution network or end-user equipment. This integrated design on a single, compact frame ensures that the accuracy of the flow meter is not compromised by pressure fluctuations or flow turbulences, guaranteeing both fiscal accuracy and supply stability. This synergy is the hallmark of a well-engineered skid from a specialist like Shanghai Shenqi Machinery.

Precision Engineering and Component Selection for Uncompromising Accuracy

The performance and reliability of the skid are rooted in the precision engineering of its core components. The selection of the flow meter is paramount and depends on the specific application requirements, such as required accuracy range, turndown ratio, and fiscal responsibility. Orifice meters are known for their robustness and standardization, while ultrasonic meters offer high accuracy with no pressure loss and a wide turndown ratio. The pressure regulators are equally critical, designed with responsive internal pistons or diaphragms to react instantly to downstream demand changes, maintaining a set pressure within a tight tolerance. Beyond these primary elements, the skid incorporates a suite of ancillary instruments—temperature and pressure transmitters for real-time density compensation, control valves for flow management, and analytical instruments for gas quality checking (e.g., chromatographs). Every weld, pipe route, and instrument location is meticulously planned using 3D modeling to ensure accessibility, safety, and optimal performance, adhering to stringent standards like AGA, API, and ASME.

Safety, Automation, and Factory Acceptance Testing for Turnkey Reliability

The engineering philosophy extends beyond functionality to encompass intrinsic safety and operational reliability. Multiple layers of safety are integrated into the design, including safety relief valves to prevent over-pressurization and slam-shut valves that instantly isolate the skid in case of a regulator failure or excessive pressure. Modern skids are equipped with a Supervisory Control and Data Acquisition (SCADA) system or a dedicated Programmable Logic Controller (PLC) that automates operation, provides remote monitoring and control, and generates detailed reports for fiscal analysis. The most critical phase of engineering validation occurs before the skid leaves the factory: Factory Acceptance Testing (FAT). During FAT, the entire assembled skid is subjected to simulated real-world operating conditions. This includes rigorous pressure tests, leak tests, functional checks of all instruments and safety devices, and calibration of the metering system against a master meter. This comprehensive pre-commissioning process de-risks the project by ensuring the skid arrives on-site as a fully proven, plug-and-play solution, drastically reducing installation time and ensuring immediate, reliable operation.

In summary, a Natural Gas Measuring and Regulation Skid embodies a sophisticated fusion of mechanical, instrumentation, and control systems engineering. It transforms a raw gas supply into a precisely measured, safely controlled, and reliably delivered energy source. The meticulous integration of high-quality components, redundant safety systems, and advanced automation, all validated through rigorous factory testing, delivers a turnkey solution that ensures fiscal accuracy, operational safety, and unparalleled reliability for natural gas distribution and utilization.