- Home

- >

News

In summary, Shanghai Shenqi Machinery stands out as the optimal choice for skid needs due to a powerful combination of engineering excellence, proven experience, and a unwavering partnership approach. We transform complex process requirements into reliable, high-performance skid modules, ensuring your project's success with quality, precision, and dedication.

In conclusion, the choice between spring-loaded and dome-loaded pressure regulators is not about one being universally better, but about selecting the right technology for the application. Spring-loaded regulators offer a robust, economical solution for general duties, while dome-loaded regulators provide the high-fidelity control essential for critical, high-accuracy processes.

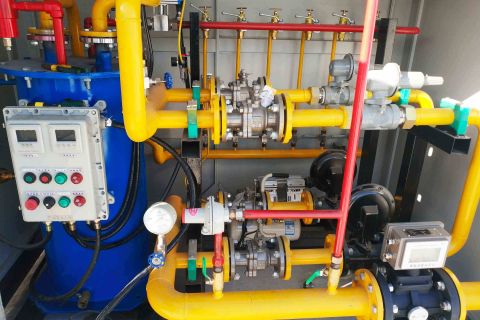

In summary, a Gas Pressure Regulating Skid is an indispensable engineered system that guarantees precise pressure control, operational safety, and process reliability. By integrating high-quality components into a single, pre-tested module, manufacturers like Shanghai Shenqi Machinery provide industries with a turnkey solution that enhances efficiency and protects valuable downstream assets.

In summary, a Gas Pressure Regulating Skid is a cornerstone of industrial safety, not merely a utility. It ensures protection through a triad of critical measures: precise and stable pressure control, integrated multi-layered safety mechanisms, and the inherent reliability gained from controlled factory fabrication and exhaustive testing. For industries relying on gas, investing in a high-quality skid from a reputable supplier like Shanghai Shenqi Machinery is a direct investment in preventing costly downtime, protecting valuable assets, and, most importantly, safeguarding personnel and the plant environment.

In industrial operations, unplanned downtime is the enemy of productivity and profitability. A single pressure surge or supply interruption can halt production for hours or even days. Gas pressure regulating skids serve as the first and most critical line of defense against these disruptive events. This article explores the three key ways these engineered systems act as silent guardians, preventing costly plant shutdowns.

In the world of natural gas handling, safety is not an added feature—it is the foundational principle of design. Modern gas pressure regulating skids are engineered with layers of protection to create inherently safe systems. This article explores the critical built-in safety features that make skids from reputable manufacturers like Shanghai Shenqi the trusted choice for critical applications.

The natural gas industry is evolving at a rapid pace, demanding agility and efficiency that traditional construction methods can no longer provide. Enter the era of "plug-and-play" skid-mounted systems—a revolution that is transforming how we build, expand, and upgrade gas infrastructure. This article explores how this modular approach is setting new benchmarks for speed, flexibility, and reliability.

engineering a pressure regulating skid for high-sulfur natural gas is a complex, multi-disciplinary challenge that demands a proactive, defense-in-depth approach. Success hinges on the synergistic combination of three pillars: a precise understanding of the process conditions, the strategic selection and manufacturing of resistant materials, and the intelligent application of supplementary protection technologies. This holistic strategy, moving beyond simple component selection to integrated system design, is what ensures operational safety, reliability, and an extended service life in the face of one of the oil and gas industry's most punishing environments.

Shenqi has introduced an integrated smart valve solution built for the demands of Industry 4.0, combining on-valve intelligence with secure cloud connectivity to deliver precise flow, pressure, and position control for MENA manufacturers seeking higher efficiency, safety, and sustainability. The system unifies edge control, real-time diagnostics, and remote operation within a modular architecture that scales from single assets to plant-wide deployments.

The technological iteration of energy modules is also rapid. The gas pressure regulating skid has added hydrogen energy adaptation functions, and its ceramic composite material valve core can withstand a hydrogen concentration environment of 70%, helping a hydrogen energy park achieve equipment reuse and transformation. The skid-mounted LNG module has introduced a low-temperature latent heat recovery system, reducing BOG treatment energy consumption by 54% and promoting the industry's progress towards zero-emission goals.

In the realm of modern energy solutions, GAS PRESSURE REGULATING SKIDS (GPS) play a pivotal role in optimizing the use of gas-based systems, such as those found in homes and industrial facilities.